2.1 Training Requirements

2.1.1 Training Frequency

CHP training must be provided:

Initially before workplace chemical use begins

At any time when:

Employee actions indicate that they have not retained knowledge or skills relating to safe chemical use.

Changes in the workplace or type of chemical used, making previous training incomplete or obsolete.

2.1.2 Training Content

Microsoft is required to provide employees with information and training to ensure that they are apprised of the hazards of chemicals present in their work area.

At a minimum, employees in hardware labs should be trained on;

This CHP,

Methods and observations that may be used to detect the presence or release of a hazardous chemical (such as monitoring conducted by the employer, continuous monitoring devices, visual appearance or odor of hazardous chemicals when being released),

The physical and health hazards of chemicals in the work area and means to protect themselves from these hazards (from the safety data sheets (SDS)),

Shut-off procedures for various equipment and utilities in case of an emergency.

2.2 General Safe Work Practices

2.2.1 Standard Operating Procedures

Each site or Business Group must develop specific procedures to manage chemicals while they are under the control of Microsoft employees. Below are general guidelines to consider when developing these procedures.

Develop a list of approved chemicals and a list of prohibited chemicals. A chemical inventory must be maintained for each Microsoft laboratory. See Appendix A. Managers may compile chemical inventory lists for specific storage locations within the laboratory as needed.

Establish a procedure for employees to request permission to purchase chemicals, submit SDS and other documentation, and assess the hazards of storing and using each chemical.

Ensure that SDS are available for each hazardous chemical present at a laboratory.

Minimize the inventory of chemicals purchased and stored to the amount necessary to support the current business processes. Unused or expired chemicals may require costly disposal.

Flammable materials should be stored in a flammables storage cabinet that has been certified by a standards-setting organization such as Underwriters Laboratories (UL).

Compressed gas cylinders should be attached to walls or other supports to prevent them from falling over and should be transported on a cart designed for that purpose.

Chemicals should be segregated as necessary to prevent dangerous chemical reactions. For example, acids and bases should be stored separately.

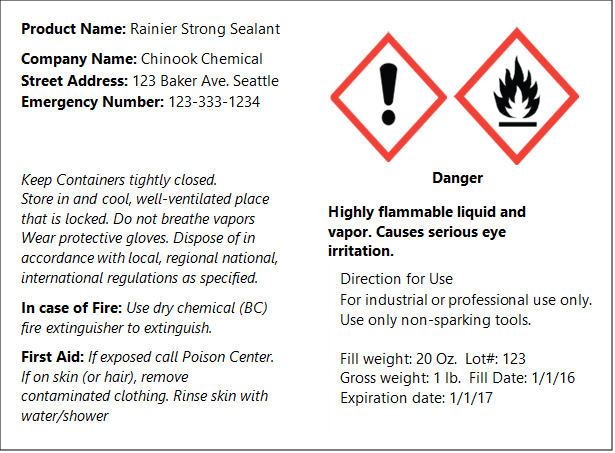

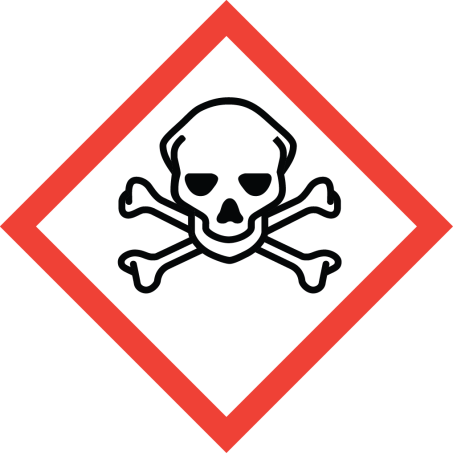

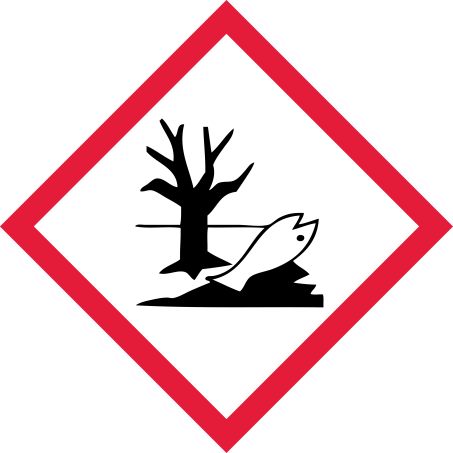

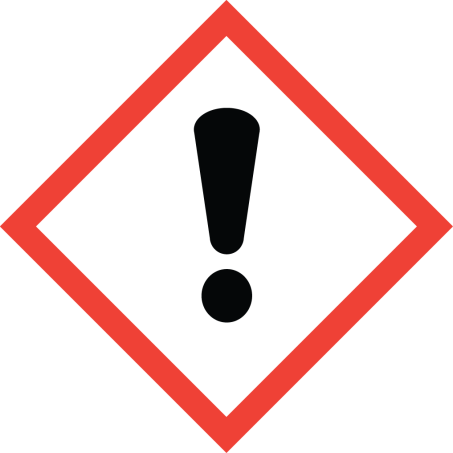

Chemical containers must be labeled to display the name of the chemical and any relevant hazards. Examples of chemical labels are shown in Appendix B.

Ensure that chemical use areas comply with local fire and building code requirements like fire suppression (sprinklers), ventilation, and escape routes.

Employees should not eat or drink in chemical use areas and should wash their hands after working with hazardous chemicals.

Chemicals that are flammable, highly toxic, or that have a strong odor should be used in a fume hood to prevent employees from breathing the vapors.

2.2.2 Personal protective equipment, engineering controls and apparel

In accordance with regulatory requirements, a hazard assessment should be conducted to identify hazards or potential hazards in the workplace and to determine if PPE is necessary for the work. PPE alone should not be relied on to provide protection for employees. PPE should be used after all other reasonable means of reducing hazards have been carried out.

PPE used must meet ANSI consensus standards.

Employees exposed to hazards that could injure their eyes and/or face use appropriate protection.

Employees working around machinery or in locations that present a hair-catching or fire hazard must wear caps or head coverings that completely cover their hair.

Use foot protection where employees are exposed to hazards that could injure their feet.

Employees exposed to hazards that could injure their hands must use appropriate hand protection. Make sure when choosing hand protection, you consider how well the hand protection performs relative to the task, conditions present, duration of use, hazards and potential hazards.

2.2.3 Laboratory equipment

Wet chemical spaces and those with higher levels of hazard should be separated from other spaces by a wall or protective barrier wherever possible. If the areas cannot be separated, then employees in lower hazard spaces may require additional protection from the hazards in connected spaces.

Work surfaces should be chemically resistant, smooth, and easy to clean

Hand washing sinks for hazardous materials may require elbow, foot, or electronic controls for safe operation.

Wet laboratory areas should have chemically resistant, impermeable, slip resistant flooring.

Walls should be finished with a material that is easy to clean and maintain.

Doors should have view panels to prevent accidents and should open in the direction of egress.

Operable windows should not be present in laboratories, particularly if there are chemical hoods or other local ventilation systems present.

2.2.4 Safety equipment

2.2.4.1 Storage of flammable liquids

Only approved containers may be used for storage and handling of flammable liquids. Only approved metal safety cans may be used for handling and use of flammable liquids in quantities 5 gallons or less. For quantities of one gallon or less, only the original container may be used for storage, use, and handling of flammable liquids.

Flammable liquids may not be stored in areas used for exits, stairways, or normally used for the safe passage of people.

All flammable liquid containers must be clearly marked to indicate their contents. Each storage container for flammable liquids, with a capacity of 50 gallons or more, must have the contents of the container identified by a sign of clearly visible contrasting colors with letters at least 3 inches high, painted on the container at the discharge valve and at the fill point.

No more than 25 gallons of flammable liquids may be stored in a room outside of an approved storage cabinet.

Quantities of flammable liquid more than 25 gallons stored in an acceptable or approved cabinet must meet the following requirements:

No more than 60 gallons of Category 1, 2, or 3 flammable liquids or 120 gallons of Category 4 flammable liquids can be stored in any one storage cabinet. Not more than three such cabinets may be in a single storage area. You must store quantities more than this in an inside storage room. See Definitions for flammable liquid category definitions.

2.2.4.2 Eyewash stations and safety showers

Provide an emergency shower when there is potential for major portions of an employee’s body to contact corrosives, strong irritants, or toxic chemicals. The shower must deliver water to cascade over the user’s entire body at a minimum rate of 20 gallons (75 liters) per minute for fifteen minutes or more.

Provide an emergency eyewash when there is potential for an employee’s eyes to be exposed to corrosives, strong irritants, or toxic chemicals. – That irrigates and flushes both eyes simultaneously while the user holds their eyes open. – With an on-off valve that activates in one second or less and remains on without user assistance until intentionally turned off. – That delivers at least 0.4 gallons (1.5 liters) of water per minute for fifteen minutes or more (See Appendix C for guideline).

2.2.4.3 Laboratory design and ventilation

Proper installation and use of laboratory exhaust hoods and local ventilation can prevent the entry of airborne material into the laboratory air. Work with hazardous chemicals should be conducted in a properly functioning laboratory exhaust hood or with other appropriate exhaust devices. Chemicals should be handled in a way that minimizes their release from the source.

2.2.4.4 Using a Hood

Stand near the center of the hood opening, at a minimum of 4" away from lip.

Since most vapors are heavier than air, do not obstruct the bottom of the hood so that air cannot be drawn across it. Obstructions will allow vapors or fumes to flow out the front of the hood, instead of being drawn away from the employee and towards the back of the cabinet.

Equipment such as steam baths, large hot plates, etc. should be elevated about 4-5 cm, or more, off the floor of the hood and located a minimum of 15 cm into the hood.

Open the hood sash only when installing apparatus. Close the sash as much as possible while working. Close the sash completely when leaving the hood or when not actively working inside the hood. Do not work in a laboratory exhaust hood with the sash open beyond the sash stop. This will result in a face velocity that is too low. The hoods are not designed to operate with the sash completely opened. Sash stops can be bypassed only for the loading of equipment or material. Exception: if there is testing documentation to show the hood meets velocity requirements with the sash fully opened.

Keep all doors in the lab closed as much as possible. Open doors cause air currents to vary, which creates the possibility of back-drafting chemical vapors.

Direct employee walking traffic patterns away from hoods where work is being performed. Set up barricades if necessary.

Do not change the air flow volume control. If a hood does not appear to be operating correctly, or odors are noticed, contact Microsoft RE&F for testing or repairs.

2.2.4.5 Hood Testing

The quality and performance of the laboratory exhaust hoods are evaluated annually to ensure that the air flow entering the hood and within the hood is not excessively turbulent. Each hood has a method for determining that it is operating. Face velocities should be between 60 - 100 feet per minute (ft/min). Excessively high air flow velocities should be avoided because they may cause turbulence and ineffective capture of chemical vapors. If the recommended face velocities are not met, the hood must be taken out of service until proper air flows are reestablished. Heat sources can lower the face velocity in the area below a sash. If heat sources are generally used, the hood should be evaluated with the heat source operating.

Microsoft RE&F will maintain a record of laboratory exhaust hood velocity evaluations and any maintenance performed. Re-evaluation of hood velocities will be performed whenever there are changes in the room ventilation systems, hood design or the hood is relocated.

2.2.4.6 Local exhaust ventilation for soldering and welding

Many potentially hazardous materials contained in fluxes, coatings, coverings, and filler metals may be released to the work area when welding and soldering. Welding on certain types of metals or on certain metal coatings may also release hazardous materials into the work area. Employees must use local exhaust or general ventilating systems when operations may generate hazardous fumes, gases, or dust. These systems can help reduce the concentration of airborne hazardous materials below the material’s permissible exposure limit (PEL).

2.2.5 Chemical management

Prudent chemical management includes the following processes:

2.2.5.1 Chemical Procurement

2.2.5.1 Chemical Procurement

Only the minimum amount of the chemical needed to perform the planned work should be ordered.

Purchases of high-risk chemicals should be reviewed and approved by the CHO.

Only chemical containers with adequate identifying labels and SDS should be accepted.

Shipments with breakage or leakage should be refused or opened in a chemical hood.

Proper PPE, handling and storage, and spill response procedures should be in place before receiving a chemical shipment.

2.2.5.2 Chemical Storage

Chemicals should be separated and stored according to hazard category and compatibility.

Consult the SDS and keep incompatibles separate during transport, storage, use, and disposal.

Maintain existing labels on incoming containers of chemicals and other materials.

Labels on containers used for storing hazardous chemicals must include the chemical identification and appropriate hazard warnings.

The contents of all other chemical containers and transfer vessels, including, but not limited to, beakers, flasks, reaction vessels, and process equipment, should be properly identified.

Peroxide formers should be dated upon receipt, again dated upon opening, and stored away from heat and light with tightfitting, nonmetal lids.

Open shelves used for chemical storage should be secured to the wall and contain 3/4-inch lips. Secondary containment devices should be used as necessary.

Oxidizers, reducing agents, and fuels should be stored separately to prevent contact in the event of an accident.

Chemicals should not be stored in the chemical hood, on the floor, in areas of egress, on the benchtop, or in areas near heat or in direct sunlight.

Do not store food or beverages in the laboratory refrigerator.

Store water reactive chemicals in a closed cabinet to prevent contact with water if the sprinklers were to activate.

2.2.5.3 Chemical Handling

A risk assessment should be conducted prior to beginning work with any hazardous chemical for the first time.

SDS and label information should be read before using a chemical for the first time.

Laboratory employees should ensure that proper engineering controls (ventilation) and PPE are in place.

2.2.5.4 Chemical Inventory

2.2.5.5 Transporting Chemicals:

Chemicals must not be transported between buildings without approval by the Chemical Hygiene Officer (CHO).

Secondary containment devices should be used when transporting chemicals in breakable containers

2.2.5.6 Shipping Chemicals

Outgoing chemical shipments must meet all applicable federal, state, and Department of Transportation (DOT) regulations and handled by an authorized shipping supplier or Microsoft Mailing and Shipping group.

2.2.6 Chemical waste management

A chemical waste management plan should be in place before any laboratory activity begins. The plan should utilize the following hierarchy of practices:

Reduce waste sources. The best approach to minimize waste generation is by reducing the scale of operations, reducing its formation during operations, and, if possible, substituting less hazardous chemicals for a process.

Reuse surplus materials. Only the amount of material necessary for an experiment should be purchased, and, if possible, materials should be reused.

Recycle chemical waste when possible. If waste cannot be prevented or minimized, the user should consider recycling chemicals that can be safely recovered.

Dispose of chemical waste properly. Proper waste disposal methods will be determined by the Microsoft Occupational Health and Safety (OHS) group.

2.2.7 Collection and Storage of Chemical Waste

- Chemical waste must be accumulated at or near the point of generation, under the control of laboratory employees.

- Each chemical waste type must be stored in a compatible container pending transfer or disposal. Waste containers must be leak-proof, clearly labeled and kept sealed when not in use.

- Chemical waste containers labels must include the accumulation start date and hazard warnings as appropriate.

- Incompatible chemical waste types must be kept separate to ensure that heat generation, gas evolution, or another reaction does not occur.

- Chemical waste containers should be segregated by how they will be managed. Chemical waste containers must be stored in a designated location that does not interfere with normal laboratory operations. Ventilated storage and secondary containment may be appropriate for certain waste types.

- Personal protective equipment must be worn by employees involved in chemical waste management, as directed by the risk assessment.

2.2.8 Housekeeping

Employee exposure to wet floors or spills and clutter can lead to slips/trips/falls and other possible injuries. To keep employees safe, managers should do the following:

Keep floors clean and dry, and provide warning (caution) signs for wet floor areas

Keep aisles and passageways clear and in good repair, with no obstruction across or in aisles that could create a hazard,

Keep exits free from obstruction. Access to exits must remain clear of obstructions

Ensure that spills are reported and cleaned up immediately.

Eliminate cluttered or obstructed work areas.

Use prudent housekeeping procedures such as using caution signs, cleaning only one side of passageway at a time, and provide good lighting for all halls and stairwells to help reduce accidents, especially during the night hours.

Eliminate uneven floor surfaces.

Promote safe work practices, even in cramped working spaces.

2.2.9 Emergency procedures for accidents and spills

Each work area must establish procedures for responding to an unintended release of or exposure to hazardous chemicals. This should include local emergency contacts and the locations of emergency response equipment like spill kits and emergency washing stations.

2.2.10 Compressed gas safety

Various compressed gas cylinders are used in laboratories. Within laboratories, compressed gases are usually supplied either through fixed piped gas systems or individual cylinders of gases. Compressed gases can be toxic, flammable, oxidizing, corrosive, or inert. Leakage of any of these gases can be hazardous. Leaking inert gas (e.g., nitrogen) can quickly displace air in a large area creating an oxygen-deficient atmosphere. The gases stored in compressed gas cylinders are under pressure of from 250 psi to 2200 psi. Special storage, use, and handling precautions are necessary to control these hazards.

2.2.11 Compressed gas cylinder storage

Always store compressed gas cylinders in a secure upright position

Always store with caps over the valves

Never store incompatible gases closely together

Never store oxygen cylinders near cylinders containing flammable gases

Avoid storing cylinders in areas of high temperatures

Separate full cylinders from empty ones

Remove empty cylinders from the work area

2.2.12 Working with compressed gas cylinders

Never tamper with any safety devices on the valve or cylinder

Always open valves slowly. Never attempt to repair valves or regulators

Do not try to transfer gases from one cylinder to another

Keep a fire extinguisher nearby when handling or working with compressed gas cylinders

When in use, keep cylinders secured to a cart designed for that use

When transporting cylinders always use a hand truck specifically designed for that purpose.

Never expose compressed gases to oil or grease. Oil and grease in an oxygen-rich environment can create a fire hazard.

Laboratories must include compressed gases in their inventory of chemicals.

2.2.13 Employee Exposure monitoring

With assistance from Microsoft OHS, managers/supervisors must characterize the nature and magnitude of employee exposures to chemical hazards before selecting PPE. The "reasonable estimate" of potential employee exposures, including those likely to be encountered in reasonably foreseeable emergency situations, must also include the physical state and chemical form of such contaminant(s).

Situations when an exposure assessment is necessary may include but are not limited to:

When OSHA or State agency has a substance specific standard (e.g., lead, methylene chloride).

When employees notice symptoms (e.g., irritation, odor) or complain of respiratory health effects.

When the workplace contains visible emissions (e.g., fumes, dust, aerosols).

2.2.14 Medical consultation, examination, and frequency

Microsoft will make available to all employees who work with hazardous chemicals an opportunity to receive medical attention when:

An employee develops signs or symptoms associated with a hazardous chemical to which the employee may have been exposed.

An employee encounters a spill, leak, explosion or other occurrence resulting in the likelihood of a hazardous exposure.

Regulatory requirements deem necessary (e.g., tight-fitting respirator use).

The identity of the hazardous chemical, a description of the incident, and any signs and symptoms that the employee may experience must be relayed to the physician.

2.2.15 Standard Operating Procedures (SOPs)

An SOP outlines how to perform work safely when it involves hazardous materials or hazardous operations. SOPs are required by Washington State L&I and OSHA. There are no specific legal requirements regarding SOP content.

An SOP must be written for the following activities

Managers are responsible for developing and maintaining SOPs for the work conducted in their labs. OHS can assist in developing these documents as needed.

2.3 Continuous Improvement

This CHP and associated forms or templates will be reviewed periodically and updated to reflect changes. Periodic work area audits will include verification of Plan elements in areas where chemical hazards are present.

Managers should conduct a periodic review of work procedures and risk assessments for hazardous chemical use for their teams. This helps ensure the documents are still accurate and that the hazard controls are adequate to protect employees. When reviewing risk assessments and work procedures, ensure that all controls are still in place and are being used, and that any required signage and training is current. If there is a need for exposure monitoring, determine whether it needs to be repeated.

Managers should review the results of workplace inspections and compliance audits. These should include a list of associated corrective actions. Inspection report review should verify that corrective actions are completed in a timely manner.