2.1 Prevention and Control

Each Microsoft location included in the scope of this program must develop a Site-specific Hoists and Cranes Safety Plan (Site Plan). The Site Plan must be made available to any personnel potentially affected by the program including employees, external staff, or regulatory agency personnel. The Site Plan must include the following:

Program purpose and scope.

Applicable federal, state, or local regulatory requirements.

Personnel roles and responsibilities.

Definitions of terms critical to an understanding of the program, or those terms not commonly understood.

Hoists and cranes safety procedures including an inventory list and standard operating procedures (SOPs).

Overhead and Gantry Crane Specifications

General Safe Work Practices

Setting up a Crane

Suspended Loads

Operating a Crane

Securing Cranes

Hoists, Hooks, Slings, and Other Rigging Equipment

PPE requirements.

Description of hazards and risk assessments.

Training records.

Incident investigations for all accidents, incidents, and near-miss incidents related to the use of hoists and cranes.

2.2 Risk Assessment

Risk Assessment is an evaluation of health and safety hazards in a work task and determining the likelihood of personnel injury or property damage resulting from those hazards. These analyses will usually include:

Interviewing supervisors, employees, and external staff.

Observing work practices.

Reviewing supporting documents that may include applicable regulations, guidelines, and SOPs.

Engaging process experts to review the tasks and develop safe work practices for operation and maintenance.

The Plan Administrator will provide recommendations of appropriate engineering controls, administrative controls, work practices, PPE, or corrective action items. Supervisors must notify the Plan Administrator when:

For more information on the risk assessment process, consult the Microsoft Exposure Assessment Program.

2.3 Hoists and Cranes Hazards

Hoists and cranes are used to move and handle heavy equipment or materials. The use of hoists and cranes results in hazards associated with the equipment (hooks, slings, rigging equipment, etc.). These hazards present the potential for property damage and personnel injury for those in the vicinity of the equipment. Some hazards associated with hoists and cranes include:

Electrocution due to contacting power lines near the work area.

Crushing hazards from crane assembly/disassembly and crane upsets or overturns.

Property or people being struck by a moving load.

Whipping hazards due to hoisting and rigging malfunctions.

People or equipment being caught or compressed in rotating or moving parts.

Falling objects from damaged hooks, slings, or rigging equipment.

Failure of bolts.

Jamming or failure of cables.

2.4 Crane Components

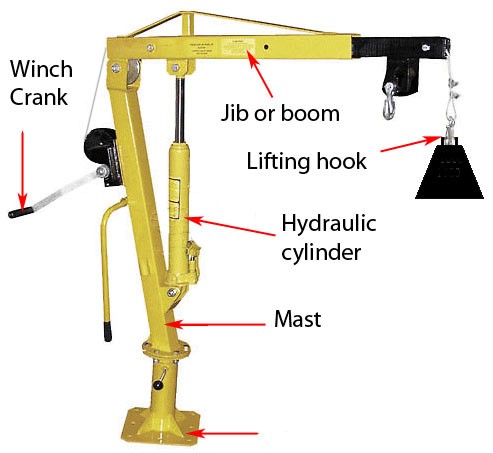

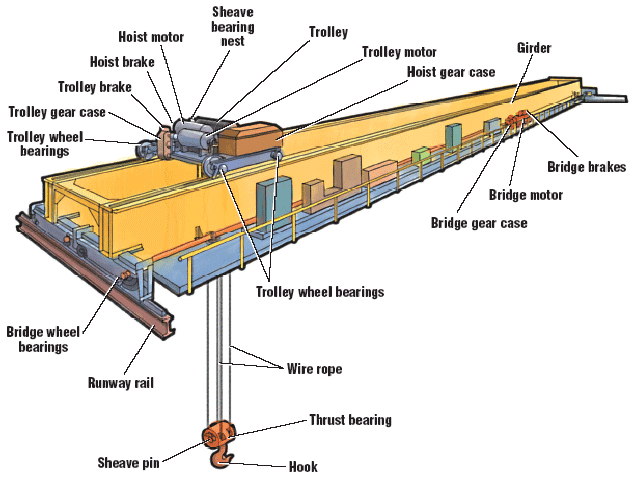

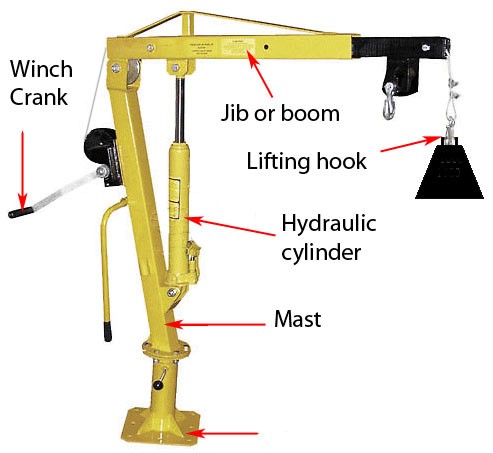

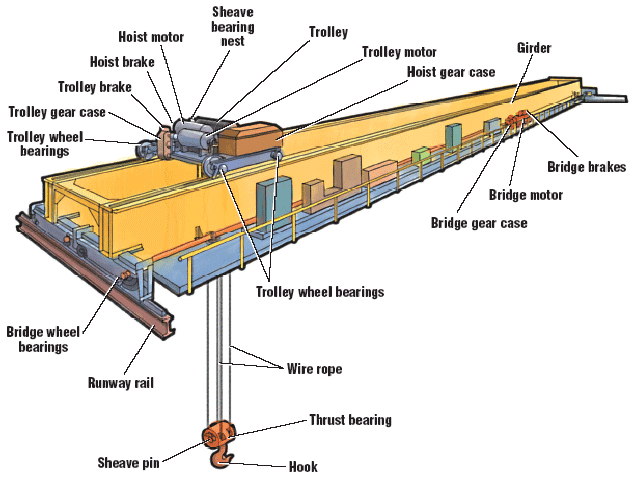

Cranes are used to lift and lower materials and to move materials horizontally within a defined area. There are several types of cranes including:

Overhead cranes

Fixed cranes

Mobile cranes

Gantry cranes

Jib cranes

Most cranes have the same general components as pictured below.

Overhead and Jib Cranes

2.5 Overhead and Gantry Crane Specifications

OSHA regulations require that overhead and gantry cranes meet the design specifications in the Safety Code for Overhead and Gantry Cranes, ANSI B30.2.0-1967. The following general requirements apply for all overhead and gantry cranes:

Any modifications made to a crane must be thoroughly checked for structural integrity and the new rated load must be approved by a qualified engineer or the equipment manufacturer.

All outdoor cranes must be provided with wind indicators and rail clamps.

Beams or building components on which the crane is attached require an engineering evaluation. The evaluation will consider the ability of the beam or building component to withstand the weight of the crane plus the load to be lifted

The rated load of a crane must be plainly marked on each side. If the crane has more than one hoisting unit, each hoist must have its rated load marked on it or its load block.

For component specifications, refer to the manufacturer’s manual.

2.6 Mobile Crane Specifications

OSHA regulations require that mobile cranes must meet the design specifications in the Safety Code for Crawler, Locomotive and Truck Cranes, ANSI B30.5-1968. The following general requirements apply for all mobile cranes:

A load chart or capacity plate should be visible to the operator at all times.

Keep loads within the equipment’s ratings.

Safety and warning devices must be operational, including buzzers, lights, and shut-off or “kill” switches.

Control access to the area using rope, barrier tape, or other barricade.

2.7 Hoisting Operations

The following general requirements apply for all hoisting operations:

Beams or building components on which the crane is attached require an engineering evaluation. The evaluation will consider the ability of the beam or building component to withstand the weight of the crane plus the load to be lifted.

Sheave grooves must be smooth and free from surface defects which could cause rope damage.

Sheaves must be properly guarded. Refer to the Microsoft Machine Guarding Program for more information.

Pockets and flanges of sheaves used with hoist chains must be designed so that the chain does not catch or bind during operation.

All running sheaves must be equipped with means for lubrication.

Hoisting ropes must be used according to the crane manufacturer’s recommendations.

The rated load divided by the number of parts of rope must not exceed 20 percent of the nominal strength of the rope.

Rope must be secured to its drum as follows:

No less than two wraps of rope can remain on the drum when the hook is in its extreme low position.

Rope end must be anchored by a clamp securely attached to the drum, or by a socket arrangement approved by the crane or rope manufacturer.

Wherever exposed to temperatures at which fiber cores would be damaged, rope having an independent wire rope or wire strand core or other temperature-damage resistant core must be used.

Replacement rope must be the same size, grade, and construction as the original rope unless otherwise recommended by the manufacturer.

Hooks must meet the manufacturer’s recommendations and cannot be overloaded.

No person should work or walk under a suspended load.

Basic hand signals should be applied for effective communication between the crane operator and signal person.

Slings, webbing, and other rigging materials must be suitable for the load and environmental conditions.

Use caution when using a guide line to stabilize or direct a load.

2.8 Personal Protective Equipment (PPE)

PPE may be required when using hoists and cranes. The Plan Administrator must work with managers to complete a Risk Assessment for any tasks involving the use of hoists and cranes. This process will identify the hazards and select the most appropriate type of hazard controls, including PPE. Before determining the appropriate PPE for the specific task, refer to the Microsoft Personal Protective Equipment Program.

2.9 Hoists and Cranes Training

All employees must be properly trained in the safe operation of hoists and cranes before they can be authorized as an operator. Authorized operators must demonstrate adequate knowledge and skills in a test environment. Several states, including Washington and California, require certification of crane operators and riggers. Certification requirements may differ if crane activities fall under construction regulations. For specific training and certification requirements, contact Global OHS.

Training manuals and services are available from equipment manufacturers. At a minimum, the authorized operator must know:

How to use the specific equipment.

How to conduct a daily equipment inspection and identify any damaged or unsafe components.

How to read a load chart.

How conditions can change once a lift begins and appropriately adjust for those changes.

Basic hand signals.

Identify hazards and how to mitigate the hazards.

Crane operators and riggers have separate responsibilities and specific training should be completed for each function; an authorized operator is not necessarily an authorized and qualified rigger.

2.10 Inspections

Users of hoists and cranes must conduct daily, monthly, and annual inspections. The equipment inspections are designed to find any components showing damage, irregularities, signs of excessive wear and tear, or other indications of compromised structural integrity.

The Site Plan should define inspection procedures based on manufacturer’s recommendations and federal, state, or local regulations.

2.10.1 Daily Visual Inspections

At the beginning of each shift operator’s shift, the operator must test the upper limit switch of each hoist without a load. Operators must complete daily visual inspections for the following potential problems:

Misalignment of any functional operating mechanisms that could interfere with proper operation.

Deterioration or leakage in lines, tanks, valves, drains, pumps, and other parts of air or hydraulic systems.

Hooks with deformation or cracks.

Hoist chains, including end connections, for excessive wear, twist, or distorted links that may interfere with proper function or that have stretched beyond the manufacturer's recommendations.

NOTE: The operator must test the brakes each time a load approaching the rated load is handled. The brakes must be tested by raising the load a few inches and applying the brakes.

2.10.2 Monthly Inspections

Operators must complete the following on a monthly basis:

Check that the rated load of the crane is plainly marked on each side of the crane.

If the crane has more than one hoisting unit, each hoist must have its rated load marked on it or its load block

This marking must be clearly legible from the ground or floor.

Inspect hooks for deformation or cracks. Inspection certification records must include the date of inspection, the signature of the person who performed the inspection, and the unique identifier (e.g., serial number) of the hook inspected.

Discard any hook where:

Repairs by welding or reshaping are not generally recommended. If such repairs are attempted, they are only to be done under competent supervision and the repaired hook’s rated load must be tested.

Test loads must not be more than 125% of the rated load unless otherwise recommended by the manufacturer. The test reports are to be given to the Plan Administrator.

Inspect hoist chains for excessive wear, twist, or distorted links that may interfere with proper function, or that have stretched beyond manufacturer's recommendations.

Inspect all functional operating mechanisms for excessive wear of components.

Test rope revving for noncompliance with manufacturer's recommendations.

Conduct a thorough inspection of all ropes and create a certification record which includes the date of inspection, the signature of the person who performed the inspection and an identifier for the ropes which were inspected.

Certification records are to be kept on file and be readily available for inspection.

Any deterioration of ropes which results in an appreciable loss of original strength, must be carefully observed and determination made as to whether further use of the rope would constitute a safety hazard.

2.10.3 Periodic Inspections

Complete inspections of the crane must be performed at 1-to-12-month intervals depending upon its duration and frequency of use, as well as the environment where the crane is located. The operator’s inspection must include the requirements listed under the daily and monthly inspections, and also include the following items:

Deformed, cracked, or corroded members

Loose bolts or rivets

Cracked or worn sheaves and drums

Worn, cracked, or distorted parts such as pins, bearings, shafts, gears, rollers, and locking and clamping devices.

Excessive wear on brake system parts, linings, pawls, and ratchets.

Load, wind, and other indicators over their full range, for any significant inaccuracies.

Gasoline, diesel, electric, or other power plants for improper performance or noncompliance with applicable safety requirements.

Excessive wear of chain drive sprockets and excessive chain stretch.

Electrical apparatus, for signs of pitting or any deterioration of controller contactors, limit switches and pushbutton stations.

2.11 Cranes Not in Regular Use

Cranes that have been out of service for more than 1 month must be inspected before being returned to use:

A crane that has been idle less than 6 months must be inspected conforming to requirements of both daily and monthly inspections.

A crane which has been idle for more than 6 months must be given a complete inspection conforming to all the requirements of periodic inspections.

Standby cranes must be inspected at least every 6 months in accordance with requirements of both daily and monthly inspections listed above.

Any ropes left idle for a period of a month or more must be given a thorough inspection before the rope may be put back into use.

The rope inspection must be for all types of deterioration and must be performed by and receive approval from an appointed person.

A certification record must be available for inspection which includes the date of inspection, the signature of the person who performed the inspection, and an identifier for the rope which was inspected.

2.12 Maintenance

Follow the manufacturer’s guidelines for use, expected wear and tear, and acceptable repairs.

Destroy or properly dispose of equipment that is damaged or worn.

Allow only authorized, qualified personnel to repair or alter components.

Return hoists and slings to the manufacturer for repair.

Proof-test all repaired hoists and slings before placing them back in service.

Do not coat or use handles that could diminish a sling’s capacity.

Do not use hoists, hooks, slings, or other rigging equipment that is damaged, defective, or excessively worn. Damaged equipment must be taken out of service immediately and be repaired or replaced.

2.13 Modifications

Improvised modifications will not be performed. If any modifications are made, they must be performed by qualified personnel and comply with the following:

Follow all manufacturers’ guidelines concerning modifications.

Before modifying equipment to meet a special purpose, see if any specialized equipment or components are available for that purpose.

The manufacturer or qualified personnel must inspect and approve all modifications to a crane to ensure that the modifications are made in accordance with ANSI standards.

The equipment’s new load limit must be appropriately displayed.

2.14 Audits

The Site Plan must be audited annually and updated as needed to correct identified deficiencies. Plan Administrators must also review any past incidents that occurred since the previous audit.

Managers and supervisors should be consulted about program improvement opportunities and be involved in implementation of needed compliance improvements. The Site Plan should be updated as needed to reflect compliance improvements resulting from the annual audit.