2.1 Prevention and Control

2.1.1 Written Portable Power Tools Plan

Each Microsoft location included in the scope of this Program must develop a Site-specific Portable Power Tools Safety Plan (Site Plan). Once developed, the Site Plan must be made available to any personnel potentially affected by the program, including employees, external staff, or regulatory agency personnel. The Site Plan must include the following elements:

Program purpose and scope.

Applicable federal, state, or local regulatory requirements.

Personnel roles and responsibilities.

A Site Safety and Health Administrator must be designated for each work location to oversee implementation of the Site Plan.

Definitions of terms critical to an understanding of the program, or those terms not commonly understood.

Job site control procedures, including safe work practices.

Portable power tools inventory and manufacturer instructions.

A training outline and schedule.

A portable power tools self-inspection checklist.

A record of accidents, incidents, and near-misses related to portable power tools.

2.1.2 Portable Power Tool Hazards

The categorization of power tools are determined by their power source. Each type of portable power tool has specific associated hazards and appropriate safe work practices are required when used.

Portable power tools may generate excessive noise, capable of causing hearing loss. Administrator may conduct a noise hazard assessment to determine whether the noise level and duration of exposure puts the employee at risk. Refer to the Microsoft Occupational Noise Control Program.

Portable power tools may present ergonomic risk factors such as vibration, awkward postures, weight, and repetitive motion. These factors should be considered during tool selection and use. Some tools may need to be counter-balanced to assist employees in handling the tool.

Portable power tools should not be used in wet conditions unless the tool is designed for that purpose.

Be aware of spark generation that may ignite flammables in the work area.

Some portable power tools, such as liquid fuel and hydraulic tools may come with a Safety Data Sheet (SDS). This document contains important information about the hazards posed by using or storing the chemical associated with the tool. It is important to know the physical and chemical properties of the substance and the proper handling procedures.

2.1.3 Risk Assessment

Risk Assessment is an evaluation of health and safety hazards in a work task and determining the likelihood of personnel injury or property damage resulting from those hazards. These analyses will usually include:

Interviewing supervisors, employees, and external staff.

Observing work practices.

Reviewing supporting documents that may include applicable regulations and guidelines and SOPs.

Conducting air and/or surface sampling, where occupational exposure limits are in question or as otherwise necessary.

Engaging process experts to review the tasks and develop safe work practices for operation and maintenance.

The Site Administrator will provide recommendations of appropriate engineering controls, administrative controls, work practices, PPE, or corrective action items. Supervisors must notify the Site Administrator when:

For more information on the risk assessment process, consult the Microsoft Exposure Assessment Program and the Risk Assessment Program.

2.1.4 Portable Power Tools Inventory

The Site Administrator must work with Lab and Facility Managers to determine the nature and quantity of tools at their facility and whether the tools are adequate for the required tasks. Consideration should be given to the following when creating the portable power tools inventory:

The power source for each power tool (electric, pneumatic, etc.):

The use of personal protective equipment (PPE).

Appropriate machine guarding requirements.

Proper operating controls and switches.

Proper hazard labeling.

Safety Data Sheets (SDSs).

Periodic maintenance and inspection of equipment.

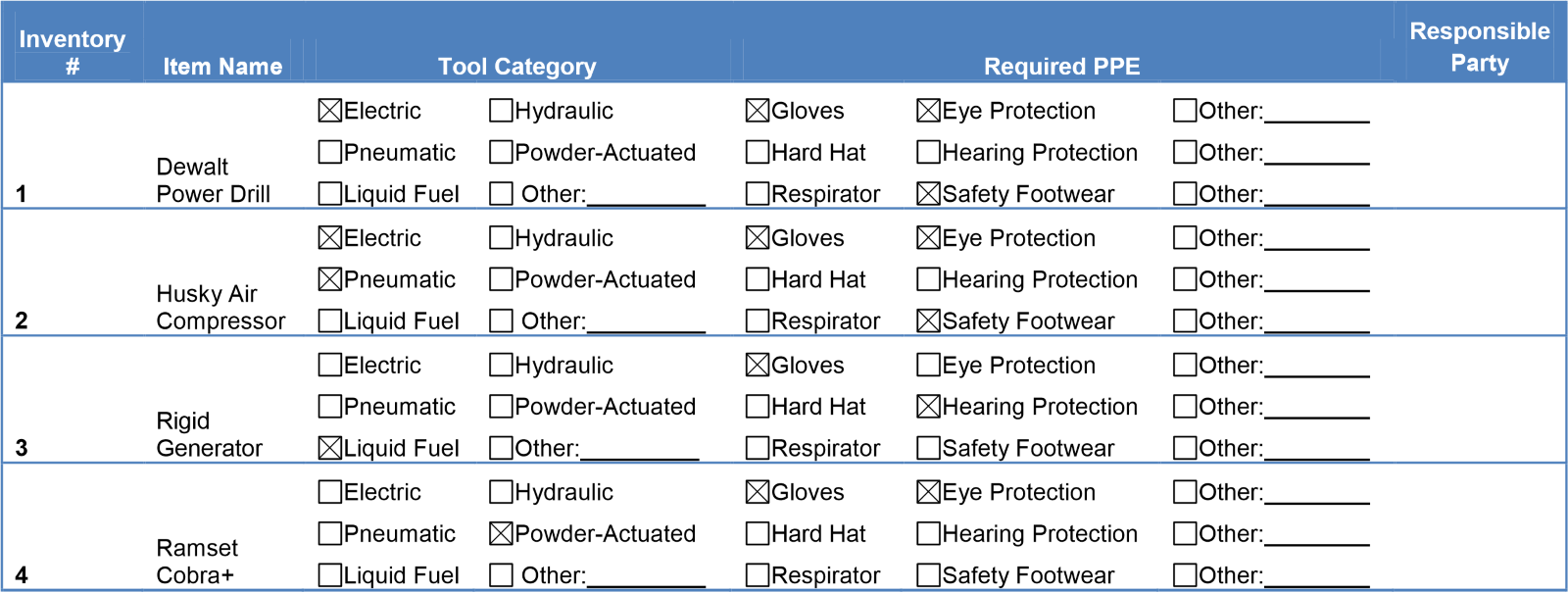

A sample portable power tools inventory registry is included in Appendix C. This inventory form may also be used to track the person responsible for the tool.

2.1.5 Guarding

The exposed moving parts of power tools need to be safeguarded, usually by shielding the moving parts and physically preventing contact with the operator. Machine guards must be provided to protect the operator and others from contacting hazards while equipment is operating.

Refer to the Microsoft Machine Guarding Program for more information.

2.1.5.1 Operating Controls and Switches

Operating controls and switches are provided by the manufacturer and designed to provide a level of safety. The following are examples of portable power tools that must be equipped with a constant-pressure switch or control that shuts off the power when pressure is released:

Drills

Tappers

Fastener drivers

Horizontal, vertical, and angle grinders with wheels more than 2 inches (5.08 centimeters) in diameter

Disc sanders with discs greater than 2 inches (5.08 centimeters)

Belt sanders

Reciprocating saws

Saber saws, scroll saws, and jigsaws with blade shanks greater than 1/4-inch (0.63 centimeters) wide.

2.1.6 Personal Protective Equipment (PPE)

PPE may be required when using certain tools or performing specific tasks. The Site Administrator must work with managers to complete a Risk Assessment for any tasks involving the use of portable power tools. This process will identify the hazards and select the most appropriate type of hazard controls, including PPE. Before determining the appropriate PPE for the specific task, refer to the Microsoft Personal Protective Equipment Program and Microsoft Respiratory Protection Program (Puget Sound).

2.1.7 Personal Tools

Use of an employee’s or external staff’s personal tools is not allowed for use on Microsoft locations or projects unless specifically authorized by the Site Administrator or Microsoft OHS in writing. Personnel should be aware that Microsoft will not be liable for any theft, loss, or damage of unauthorized personal tools on the project site. If authorized, personal tools are subject to the same safety requirements as Microsoft supplied tools and equipment.

2.1.8 Training

A competent person must train employees and external staff on the proper use and maintenance of each portable power tool in the inventory prior to the employees using the tool. The Lab or Facility Manager is responsible for ensuring that all portable power tool users have appropriate training prior to using the tool. Employees and external staff must be informed of portable power tool hazards prior to beginning work. Employees will receive training at the time of assignment. The training program must include the following information:

Applicable federal, state, or local regulations.

A summary of the Site Plan and how to access the written program.

The different types of portable power tools the employee may be using, and the hazards associated with those types of portable power tools.

The proper use of each type of portable power tools, including the proper use of hazard controls (administrative, engineering, and PPE).

Procedures for reporting and responding to an incident.

2.1.9 Audits

The Site Plan must be audited annually and updated as needed to correct identified deficiencies. The Site Administrator must also review any past incidents related to machine guarding that occurred since the previous audit.

Managers and supervisors should be consulted about program improvement opportunities and involved in implementation of needed compliance improvements. The Site Plan should be updated as needed to reflect regulatory changes and improvements resulting from the annual audit.

2.1.10 Inspections

All tools must be inspected prior to use by the person authorized to use the tool. Damaged tools must not be used. The following conditions should be evaluated and verified prior to starting the work and using the tool:

Proper general condition of tools, electrical cords, and air hoses.

Presence and serviceability of guards and safety devices.

Proper electrical grounding or double insulation protection.

Functionality of constant pressure switches.

Proper adjustment of the tool.

Whether an appropriate tool is available for the job and has the appropriate rating for the work to be performed.

Tools should also be inspected by the user at the end of work to ensure that it remained in the same safe condition. Unsafe tools must be tagged “Do Not Use” and removed from service immediately. The manager must be advised of the problem and consulted for proper corrective action. Tools tagged for repair must be physically segregated from any acceptable tools.

Formal inspections will be facilitated by the Site Administrator annually or more frequently depending on the tasks performed and how often the tools are in use. An inspection checklist is provided in Appendix B.