2.1 Prevention and Control

2.1.1 Site Confined Space Plan

The Plan Administrator for a Microsoft facility included in the scope of this program must develop a Site-specific Confined Space Plan (Site Plan). The Site Plan must be made available to employees, external staff, or regulatory agency personnel. The Site Plan must include the following:

- Program purpose and scope.

- Applicable federal, state, or local regulatory requirements

- Personnel roles and responsibilities with identification of confined space supervisors, entrants, and attendants by name.

- A Plan Administrator must be designated for each work location to oversee implementation of the Site Plan.

- Definitions of terms critical to an understanding of the program.

- Summary of the workplace survey and hazard assessments

- Entry procedures including general rules for program implementation

- Training and recordkeeping requirements

2.1.2 Hazards

The following table contains descriptions of potential confined space hazards.

WARNING: Hazardous substances that are produced by activities in the general area of a confined space can migrate to, and accumulate in the space, creating an unseen hazard to an unsuspecting entrant.

Hazard

| Description

| Safety Procedure

|

Excess Pressure

| Pressure can build up due to chemical reactions of equipment or materials inside a tightly sealed space and create a physical hazard while removing the cover or hatch.

| Entry points and hatches should be inspected prior to removal for signs of:

Discoloration

Heat

Damage around the sealing surface

|

Atmospheric

| Hazardous concentrations of chemicals may build up or be generated in the confined space, posing a respiratory hazard to the entrant.

| Use calibrated confined space monitors prior to entry, and continuously during entry, to test for hazardous atmospheres, including:

Oxygen 19.5 to 23.5%

Flammability (% of LEL) < 10%

Carbon Monoxide < 35 ppm

Hydrogen Sulfide < 10 ppm

Specific testing as needed

|

Electrical

| Confined spaces may contain equipment that poses electrical hazards such as defective cables, water in contact with a source of electricity, or through physical contact with charged cables or wire leads.

| Follow requirements in Microsoft

Electrical Safety Program and Microsoft

Control of Hazardous Energy (LOTO) Program

|

Engulfment

| Engulfment hazards in a confined space are created by conditions that could crush, suffocate, trap, or incapacitate an entrant.

| Visually inspect the space prior to entry to evaluate potential engulfment hazards. Control engulfment hazards before entering the space using such devices as trench boxes.

Apply appropriate LOTO procedures if the engulfing material has the potential to enter during work

|

Entrant-

Generated

| Bringing chemicals into the space (such as for cleaning, painting, stripping, or coatings) can create a toxic, flammable, or oxygen deficient atmosphere. Hot work can create additional flammable and ignitable hazards.

| Review SOP for entry into the confined space.

Anticipate the hazards associated with the task.

Implement controls to prevent an incident.

|

2.2 Confined Space Hazard Assessment

The Site Facility owner will conduct a survey to identify and classify all permit and non-permit required confined spaces present at the Microsoft-owned facilities. The survey must include an inventory of all confined spaces. The complete inventory includes documentation of the following:

- Identification of each space by unique identifying number

- Photograph(s) of entry points or exterior hazards for each space

- Determination of non-permit/permit-required classification for each space.

- Identification of unique hazards found in the space that need to be mitigated or controlled before entering the space.

- Historical information, if available, of atmospheric monitoring.

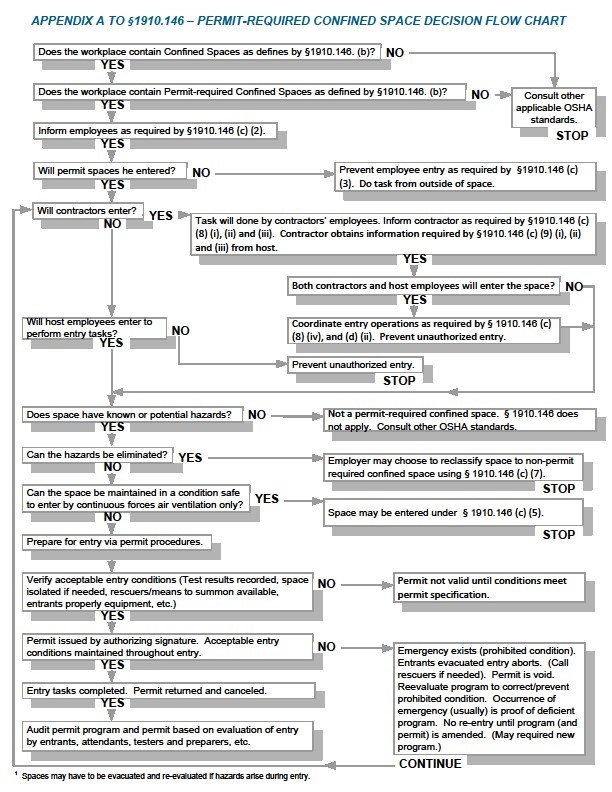

Based on the hazard assessment, the Plan Administrator will determine whether the space is non-permit or permit required using OSHA’s Permit-required Confined Space Decision Flow Chart (Appendix C).

- The Entry Supervisor should develop an entry SOP describing the work to be performed in the space (Appendix D).

- If the Plan Administrator confirms that different confined spaces share identical entry requirements, the same SOP may be re-used for more than one confined space.

2.2.1 Non-Permit Confined Spaces

- A non-permit confined space meets the OSHA definition of a confined space but does not contain any physical or atmospheric hazards nor is there a potential for these hazards to develop.

- If the potential for a hazardous atmosphere to develop during entry exists, the space cannot be classified as a non-permit confined space.

2.2.2 Permit-Required Confined Space

For a space to be classified as a permit-required confined space it must have one or more of the following characteristics:

- Contains or has the potential to contain a hazardous atmosphere.

- Contains a material that has the potential for engulfing an entrant.

- Has an internal configuration such that an entrant could be trapped or asphyxiated by inwardly converging walls or by a floor which slopes downward and tapers to a smaller cross-section.

- Contains any other recognized serious safety or health hazard.

2.2.3 Reclassification of a Permit-Required Confined Space

- A permit-required confined space may be reclassified as a non-permit confined space as long as the non-atmospheric hazards remain eliminated.

- A permit-required space with atmospheric hazards may not be reclassified.

- Use of ventilation is not sufficient to allow re-classification of the space.

- If entry into the permit-required space is required to eliminate hazards, the entry must be completed under permit-required conditions.

- Once non-atmospheric hazards have been eliminated, the permit-required space may be reclassified as a non-permit confined space for as long as the hazards remain eliminated.

- The Entry Supervisor must verify that all hazards in a permit-required space were eliminated.

- The verification must contain the date, the location of the space, and the signature of the Entry Supervisor. The verification shall be made available to all entrants.

- If hazards arise within a reclassified space, all entrants must exit the space. The Entry Supervisor must reevaluate the space and determine whether it must be reclassified as a permit space.

Contact the Plan Administrator, or Microsoft OHS for more information on reclassifying a permit-required confined space.

2.3 Identification of Confined Spaces

All non-permit and permit required confined spaces must be identified with a danger sign.

- Non-permit spaces will be identified with a signs stating:

- Permit required confined spaces will be identified with a danger sign that states:

- Confined spaces, whether non-permit or permit required, should be identified by a unique name and documented on the confined space assessment for that unique space.

- New spaces may be added to the inventory, or the hazard assessment may require updating if hazardous conditions change.

- If a space does not have a signed and does not have a documented hazard assessment, the entrant shall not enter the space and should immediately notify the Plan Administrator to determine the proper entry procedures.

2.4 Confined Space Entry

2.4.1 Pre-Entry Requirements for Confined Spaces

A Confined Space SOP must be prepared and reviewed by all Entry Team members before entering a space. The Entry SOP will identify all hazards generated in the course of the work. For an example of an Entry SOP refer to Appendix D.

The Entry Supervisor must complete the following prior to entry:

- Oversee air monitoring performed prior to entry

- Notify the supervisor in charge of the area where the space is located that an entry will take place.

- Review the SOP and previous hazard assessments with the Entry Team members.

- Determine if there have been any changes in the use or configuration of the space that will change its classification.

- Determine if any activities in the area could cause a hazardous atmosphere to build up in the space.

All entrants must adhere to the following:

- Review the Entry SOP and the Confined Space Permit prior to entry.

- Enter the space only under the direction of the Entry Supervisor.

- Never perform activities in the space that could cause a buildup of a hazardous atmosphere without prior authorization.

- Never work alone.

2.4.2 Entry Procedures

An entry has occurred once any part of the body breaks the plane of an opening of a space. This includes an individual body part (e.g., an arm to make a quick adjustment or inserting the head to look inside the space). If any entry occurs, all confined space procedures must be followed.

- Specific entry requirements for each space listed in the SOP must be followed.

- Floor entrance covers that are removed should promptly have the opening guarded by a railing, temporary cover, or other temporary barrier.

- Atmospheric monitoring must be performed.

2.4.3 Entry Permits

A confined space permit, signed by the Plan Administrator, must be posted at all entrances to the space and made available to entrants before entry. See Appendix E for an example of a confined space permit.

- The permit must document that pre-entry preparations have been complete.

- The duration of entry permits must not exceed the time required to complete an assignment or the length of one 8-hour shift, whichever is shorter.

- For entries extending beyond one 8-hour shift, a new permit must be completed and signed by the respective parties involved in the entry.

- Entry permits must include:

- Name of permit space to be entered, authorized entrant(s), eligible attendants and individuals authorized to be entry supervisors.

- Air monitoring results and the tester’s initials or signature.

- Name and signature of entry supervisor.

- Purpose of entry and known confined space hazards.

- Measures to be taken to isolate permit spaces and to eliminate or control confined space hazards.

- Name and telephone numbers of rescue and emergency services and means to be used to contact them.

- Date and authorized duration of entry.

- Acceptable entry conditions.

- Communication procedures and equipment to maintain contact with the entrants during entry.

- Additional permits (i.e., hot work, energized electrical work) issued for the permit-required space.

- Special equipment and procedures, including personal protective equipment and alarm systems.

- Any other information needed to ensure employee safety.

- The Plan Administrator must cancel entry permits when:

- An assignment is completed; or

- When conditions change, such as the completion of a work shift or introduction of a hazard into the space.

- New conditions must be noted on the canceled permit and used in revising the permit.

- All canceled entry permits must retain for at least one year

2.5 Entry Team

2.5.1 Entry Supervisors

Entry supervisors are responsible for maintaining safe working conditions for the entrant and attendant while a confined space entry is occurring. The entry supervisor must:

Prior to entry

- Know about the hazards that may be faced during entry, including the mode, signs or symptoms, and consequences of the exposure.

- Verify and check all of the following prior to entry:

- Authorized members of the entry team are present.

- The appropriate entries have been made on the permit.

- All tests specified by the permit have been conducted. Attendants and entrants must have the opportunity to observe air monitoring.

- Rescue services are available and means of contact verified.

- Establish and confirm communication methods between attendant, entrant and emergency services.

- All equipment specified by the permit is in place.

- Users are trained on the SOP.

- Authorize the entry into a permit-required confined space by acquiring, reviewing, completing, and signing the entry permit. During entry operations.

- Oversee entry operations.

- Remain at the site during all entry procedures.

- An entry supervisor may oversee multiple entries at one time as long as the spaces are within visual range.

- Prohibit untrained, unauthorized individuals from entering or attempting to enter the permit-required confined space.

- Verify that the space remains safe for entry at regular intervals as dictated by the SOP.

- Terminate the entry and cancel the permit when:

- The assigned task or job has been completed.

- Conditions not covered by the permit are found.

- A condition covered by the permit and controlled before entry poses a hazard.

- Work continues past the time allocated on the permit without the authorization of the Plan Supervisor.

- Determine that entry operations remain consistent with the terms of the entry permit and acceptable entry conditions are maintained whenever responsibility for a permit-required space entry operation is transferred. If the entry operation is transferred, a new permit must be completed and signed.

After completing entry

- Complete entry permit and return to the Plan Administrator.

- Ensure that the confined space is secure, any hazards have been eliminated, and equipment used for entry is in good working order and returned to the proper storage place.

- Any equipment not in proper working order must be red-tagged with “Do Not Use” and repaired or replaced.

2.5.2 Entry Attendants

The number of attendants assigned should be tailored to the requirements of the space and the work performed. A confined space entry attendant must:

- Support only one confined space entry at a time. Attendants may not oversee more than one confined space simultaneously.

- Understand the hazards that may be faced during entry, including the mode, signs or symptoms, and results of exposure to the hazards.

- Carry out no additional duties that might interfere with monitoring and protecting the entrants.

- Continuously maintain an accurate count of entrants in the space.

- Communicate with entrants as necessary to monitor their status or alert them of the need to evacuate the space.

- Monitor activities inside and outside the space to determine if it is safe for entrants to remain in the space.

- Order entrants to evacuate the space immediately if any of the following conditions occur:

- A prohibited condition arises, such as an exceedance of acceptable atmospheric levels or failure of air monitoring instrumentation.

- The entrant exhibits behavior indicative of a hazardous atmosphere or other exposure.

- A situation occurs outside the space that could endanger entrants.

- The attendant cannot effectively and safely perform all their assigned duties.

- Warn unauthorized persons to stay away from the space.

- Perform non-entry rescues only as specified by the Confined Space Permit.

- Call for rescue and other emergency services as soon as entrants may need assistance to escape from the space.

- Monitor entry operations until relieved by another attendant or all entrants have exited the space.

2.5.3 Entrants

Confined space entry supervisors must ensure that all entrants:

- Review and understand the SOP and confined space entry permit.

- Know the hazards they may face during entry, including:

- Methods of exposure to a hazard.

- Signs or symptoms of the hazard.

- Results of exposure to the hazards.

- Have the opportunity to observe air monitoring.

- Use equipment and PPE properly.

- Communicate with the attendant as necessary so the attendant can:

- Monitor entrant status.

- Alert entrants of the need to evacuate.

- Alert the attendant whenever the following situations exist:

- A warning sign or symptom of exposure to a hazardous condition.

- A prohibited condition.

- Exit from the permit-required confined space as quickly as possible when one of the following occurs:

- The attendant or entry supervisor gives an order to evacuate.

- The entrant recognizes any warning sign or symptom of exposure to a hazardous situation.

The entrant detects a prohibited condition. An evacuation alarm is activated. Procedures for responding to and reporting an incident.

2.6 Emergency Rescue Procedures

If the confined space monitor goes into alarm or another situation arises that warrants an evacuation:

- The attendant and supervisor must ensure the entrants are immediately alerted, of hazards outside the confined space. If the hazard is inside the confined space, the entrant should notify the attendant immediately.

- The entrant should calmly and immediately exit the space under the supervision of the attendant and the entry supervisor.

- If the entrant is faced with an emergency where they are unable to self-rescue, the entry supervisor should initiate rescue procedures.

WARNING: It is crucial that members of the confined space entry team do not attempt to rescue an entrant in emergency situations to prevent further injuries, illness, or fatalities.

Each location must have a designated emergency rescue team that is trained and qualified to perform confined space rescues in both permit and non-permit spaces.

- The Plan Administrator will develop and implement procedures for:

- Summoning rescue and emergency services.

- Rescuing entrants from permit spaces.

- Providing necessary emergency services to rescued employees, and for preventing unauthorized personnel from attempting a rescue.

- The rescue team must meet the requirements of OSHA, 29 CFR 1910.146, Appendix F (Non-Mandatory) – Rescue Team; or Rescue Service Evaluation Criteria (Appendix G).

- If a local Fire Department has been chosen as the Rescue Team, the Plan Administrator must contact the Fire Department to confirm:

- They are able to support rescue operations; and

- Are aware of the unique hazards of the spaces on site.

Location specific procedures must be included in the Site Plan.

2.7 PPE

Before determining the appropriate PPE for the specific task, refer to the Microsoft Personal Protective Equipment Program. The Plan Administrator must work with managers to complete a hazard assessment for each space, which will identify the hazards and select the most appropriate type of hazard controls. The hazard assessment should include hazards from atmospheric conditions, energy sources, and other hazards for the specific work task.

2.8 Confined Space Training

Employees, external staff, vendors or contractors authorized to supervise, attend, or enter confined spaces, must be properly trained. Confined space training is required for authorized personnel prior to initial assignment and retrain if any of the following occur:

- Changes in procedures.

- Changes in work assignments.

- New hazards arise in the work place.

- An accident, incident, or near mishap occurs related to confined spaces.

- An employee demonstrates inadequacy in knowledge or competency.

Special “hand’s on” training must also be performed annually by the confined space entry team for all types of rescue including emergency, non-emergency, and self-rescue.

Microsoft OHS has defined training to meet regulatory requirements for confined space entry. To obtain training, contact Global OHS.

- The training program must include the following information for all members of the entry team:

- An overview of confined space requirements and “hand’s on” instruction on the applicable Site Plan.

- Applicable federal, state, or local regulations.

- Summary of the Microsoft Confined Space Program and how to access the Site Plan.

- Identification of personnel authorized for confined space work, by name.

- How to recognize and control permit space hazards.

- How to conduct atmospheric monitoring, specific to the equipment used at the site, and including how conditions affect sampling results.

- Signs and symptoms of atmospheric hazards that may be encountered in a confined space.

- When and how to remove hazardous atmospheres for confined spaces at the site.

- Procedures for responding to and reporting an incident.

- The use and maintenance of PPE and rescue equipment.

2.9 Audits and Inspections

Each Site Plan must be audited annually and updated as needed to correct identified deficiencies, and visually confirm and update the site inventory.

- The audit includes an annual review of cancelled permits.

- The Site Administrator must review incidents that occurred since the previous audit.

- Audits must be documented and include the inspection date, inspected equipment, the Plan Administrator’s name, and the names of all authorized entrants, attendants, and supervisors.

- Following an audit, additional training or other corrective action plans must be implemented as required to correct deficiencies.

Managers and supervisors should be consulted about program improvement opportunities and be involved in implementation of needed compliance improvements. The Site Plan should be updated as needed to reflect compliance improvements resulting from the annual audit.