Microsoft managers may use this outline to produce a written Lockout/Tagout (LOTO) Site Plan for machines, equipment or processes under their control. Please refer to Purpose and Scope for information on the applicability of LOTO to a specific area or facility. The site-specific written plan must be tailored to identify or comply with the following:

Managers must make the written LOTO Site Plan available to employees, contractors, and corporate or regulatory compliance officers.

Purpose

State the purpose of the Site Plan (ensure that personnel render onsite machines and equipment safe through isolating energy sources, prior to service and maintenance, and preventing equipment from unexpected startup, energizing, or releasing stored energy).

Scope

Describe the area or facility-specific operations that fall under this Site Plan (servicing or maintenance of machines or equipment when the energy source is electrical, mechanical, hydraulic, pneumatic, chemical, thermal, or other types of energy).

Regulations

A list of any applicable federal, state and local regulations must be included here. For example, in the United States, federal regulations for LOTO fall under 29 CFR 1910.147, “Control of Hazardous Energy (Lockout/Tagout)”. However, individual states or local municipalities may have additional requirements.

Roles and Responsibilities

Personnel with responsibility for oversight or implementation of the LOTO Site Plan must be identified here. This list need not include the names of specific individuals, but a specific job title and a summary of their role and area of responsibility must be included.

Authorized and Affected Personnel

Identify all of the authorized and affected employees for each machine, equipment or process that fall under the LOTO Site Plan. It is possible that the authorized employee is also the affected employee, if the authorized employee's task involves work on the same machine where lockout/tagout was implemented.

Workplace Survey and Hazard Assessment

Summarize the workplace survey and hazard results for energy-source hazards at the workplace. This summary can be presented as a table for easy reference. Be sure that the summary allows the reader to easily identify the referenced machine, equipment or process on the workplace floor. This can be done by including photographs or floor maps in the document.

Energy Control Procedures

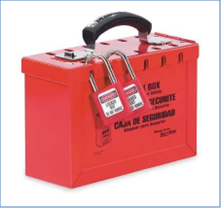

This section must include the rules or requirements for LOTO implementation. For machines, equipment, or processes that qualify for LOTO, this section must describe step-by-step procedures for LOTO (setup and removal), any operating restrictions, how authorized employees must account for affected employees, and special circumstances, such as group LOTO, multiple shift LOTO transfers, or forcible removal of a lock.

The LOTO procedures for some machines, equipment or processes may not require specific written documentation, and personnel may use a more generic LOTO procedure instead. To exclude a tailored written description from the program, the manager must verify that ALL of the following conditions exist:

Regulations applicable to the facility location do not prohibit this exclusion;

Employees will not be endangered by stored or residual energy, or re-accumulation of stored energy, in the machine or equipment after shutting down;

Only one energy source, one that employees can easily identify and isolate, provides energy for the machine or equipment;

Isolating and locking out that single energy source completely de-energizes and deactivates the machine or equipment;

Personnel performing service or maintenance always isolate and lock out the machine or equipment from that energy source;

The use of a single lockout device achieves a locked-out condition;

The authorized employee completing servicing or maintenance retains exclusive control of the single lockout device;

Servicing or maintenance does not create hazards for other employees; and

There have been no accidents that can be attributed to this exception during servicing or maintenance.

If all of these conditions cannot be met, then the written LOTO Site Plan must contain step-by step instructions for LOTO tailored specifically for the machine, equipment or process.

Some activities that take place during normal production operations, such as minor tool changes and adjustments, may not require LOTO. These types of activities must be routine, repetitive, and integral to the use of the machine or equipment during production. These activities must be called out in the written program, and still must provide an effective means of protecting personnel from harm.

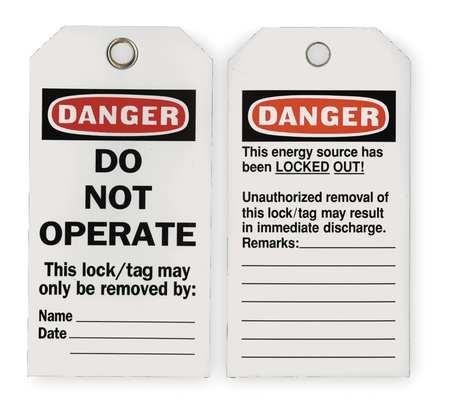

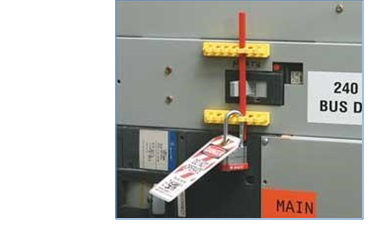

LOTO Devices

Provide a summary of information on the lockout/tagout devices used at the site or facility. This information can also be presented as a table. Be sure to include how LOTO devices are identified, that the devices comply with regulatory standards (durable, standardized, substantial and identifiable), and information on the process for issuing or approving LOTO devices used by personnel.

Training

Information on training frequency and site-specific training content must be incorporated in this section.

Inspections

Two types of annual inspections must be part of the LOTO Site Plan. The first involves an audit of the equipment-specific procedures. This allows for the identification and correction of deficiencies in the procedure. The second is an evaluation of the LOTO Site Plan as a whole, to identify and eliminate roadblocks to implementation or communication.

A crucial part of programmatic inspection is the involvement of all levels of personnel, including authorized and affected personnel, supervisors, managers and contractors. Proper implementation requires upwards and downwards communication, strong reporting requirements (near miss, incident, and accident reports), and effective corrective/preventative actions plans. These important components should be specifically evaluated in the annual LOTO Plan review.