Lab safety manual

| Program name | Laboratory Safety Program |

| Owners | Microsoft Global Occupational Health and Safety |

| Revision date | Revision B, December 9, 2022 |

| Effective date | December 9, 2022 |

The controlled version of this document can be found on the Global OHS website at aka.ms/SafetyHubPrograms. Printed copies may be out of date and should be destroyed or marked as archived immediately after use.

Senior Management endorses this Program. This document applies to all Microsoft employees and interns. This program also applies to external staff who are supervised directly by Microsoft employees and who work at a Microsoft worksite. Any violation of this Program may lead to disciplinary action up to and including termination of employment. In some cases, a violation of this Program may also violate international, federal, state, and/or local law. In such cases, Microsoft and/or the individual could be subject to civil or criminal liability.

1.0 Purpose and Scope

1.1 Purpose

Microsoft has committed to create, maintain, and enhance a safe and healthful environment for all individuals, including Microsoft Full-Time Employees (FTEs), External Staff, and Visitors. These groups are collectively referred to as “Laboratory Workers” for the purposes of this Lab Safety Manual.

This manual includes specific requirements for Laboratory Workers in many common topics that apply to work in Microsoft labs. For more in-depth information on Microsoft Occupational Health and Safety (OHS) Programs, refer to local OHS Plans. Examples of these plans include the Laser Safety Plan or the Respiratory Protection Plan.

1.2 Scope

The laboratory (lab) environment can be a hazardous place to work. Laboratory Workers are exposed to numerous potential hazards including physical, chemical, biological, and radiation hazards as well as musculoskeletal stresses.

This Lab Safety Manual sets guidelines and standards for Microsoft laboratories in Washington and California. It is based on the regulations below, used as a baseline for our lab safety practices. Federal and State requirements for safety in laboratories include:

The Occupational Safety and Health Administration (OSHA)

Washington Administrative Code (WAC)

California Code of Regulations (CCR)

2.0 Introduction

The goal of this Lab Safety Manual is to minimize the risk of injury or illness to Laboratory Workers by ensuring that they have the training, information, support, and equipment needed to work safely in the laboratory. The standards in this manual are designed to:

Protect people from injury and illness and protect property and the environment from damage, loss, or degradation due to accidents or other causes.

Comply with the requirements and guidelines of OSHA, state-specific, and local requirements.

Describe the detailed and technical work processes and administrative procedures used to control hazards in the lab spaces.

3.0 Training

All Laboratory Workers, including interns, are required to complete Laboratory Safety Training. This training gives an overview of general laboratory safety principles, references and resources for more specific safety information, and details about several support programs. The specific training courses you take are based on the hazards of the work you do.

OHS provides training, resources, and consultation for a variety of laboratory safety issues, including chemical safety, laser safety, radiation safety, electrical safety, and other topics, as covered in this document.

To request or access additional training or view your training transcript, please refer to the Online OHS Training. Some courses are offered only in person. Your training needs may also be defined by Risk Assessment and documented in the Risk Assessment Form and/or SOP.

For the diverse laboratory work conducted at Microsoft, there are several types of training requirements. Refer to the training guide in Appendix A based on Washington Department of Labor and Industries (L&I) and California Occupational Health and Safety Administration (Cal/OHSA) requirements. Washington State L&I also has several useful trainings resources available. See Appendix A for more information on these specific training topics and requirements.

4.0 General Safe Work Practices

| Topic | Safe Work Practice | Applicable Regulations and Guidance |

| Battery Safety | Battery failure (in either performance or safety) can be caused by poor design or an unanticipated use or abuse of a battery. Batteries can contain toxic and corrosive materials and, if damaged, can be a safety issue. The thermal stability of materials within the battery at high temperatures and the occurrence of internal short circuits may lead to fires. | These groups provide instruction on battery safety for charging, storage, and maintenance areas. Institute of Electrical and Electronics Engineers (IEEE) 1625 and 1725 National Electrical Manufacturer’s Association (NEMA) C18.2M International Electrotechnical Commission (IEC) IEC 62133; United Nations Manual of Tests and Criteria, Part III, Section 38.3 US Department of Transportation (DOT): 49 CFR Subchapter C – U.S. Hazardous Materials Regulations |

| BBP | The OSHA Blood-Borne Pathogen Standard applies to all Employees who have occupational exposure to blood or other potentially infectious materials (OPIM) including the potential for needlestick injuries. The BPP standard does not apply to Good Samaritan application of first aid. For those teams who may have contact with biological materials like blood or other body fluids program requirements are to have a risk assessment, to have HBV vaccination and safety training. | OSHA |

| Ergonomic Safety | Laboratory Workers are at risk for repetitive motion injuries during routine laboratory procedures such as working at microscopes, using cell counters, keyboarding at computer workstations, and other tasks. Repetitive motion injuries develop over time and occur when muscles and joints are stressed, tendons are inflamed, nerves are pinched, and blood flow is restricted. Working in awkward positions in laboratory hoods/biosafety cabinets can also present ergonomic problems. |

|

| Fire Safety | Labs, especially those using solvents in any quantity, have a high potential for fires, explosion, rapid spread of fire, and high toxicity of products of combustion. Furthermore, maintaining an uncluttered lab and corridors helps to keep exits unobstructed in the event of a fire. | Washington State L&I outlines the requirements for portable fire extinguishers, exit routes, and alarm systems. Cal/OSHA also has requirements for portable fire extinguishers, firefighting safety, and fire prevention. |

| General Chemical Safety | Laboratory chemicals can pose a safety risk from contamination, burns, and explosions if not used properly. Handle chemicals safely, minimizing the hazard to public and personal health | Chemical Safety in Labs OSHA |

| Hazard Communication | Information about the identities and hazards of the chemicals must be available and understandable to Employees. | Regulations for Laboratories |

| Ionizing Radiation Safety | Ionizing radiation sources at Microsoft currently are X-ray sources from photomultiplier tubes. However, some materials are radioactive. Whatever the source, ionizing radiation can have a significant health risk to Affected Employees if not controlled properly. | Washington State L&I Cal/OSHA, and OSHA provide technical and regulatory information regarding the safety and health hazards associated with ionizing radiation. |

| Lasers | Lasers are used in a wide variety of workplaces, including labs, manufacturing, health care, and other settings. While they can make certain tasks easier, lasers do have unique hazards and need to be treated with care and respect. | Washington State L&I has set exposure limits for lasers. In addition, OSHA, Cal/OSHA, ANSI Z136.1, and the Laser Institute of America have established regulations and guidance for the safe use of lasers. |

| Lead Safety | Lead is an ingredient in many widely used products, including lead-based paints, lead solder, electrical fittings and conduits, and various metal alloys. Although many uses of lead have been banned, lead-based solder and other products are used due to its desired properties. Significant lead exposures can occur during soldering, welding, and other processes from airborne or surface borne routes. |

Washington State Labor & Industries, Cal/OSHA, and OSHA regulate the use of lead in the workplace. |

| Noise | Occupational hearing loss is one of the most common work-related illnesses in the United States. Each year, about 22 million U.S. workers are exposed to hazardous noise levels at work from noisy machines, tools, processes, and other sources. | Washington State L&I, Cal/OSHA, and OSHA have established programs for Hearing Loss Prevention in the workplace. |

| Non-Ionizing Radiation (non-lasers) Safety | Non-ionizing radiation is described as a sequence of energy waves composed of oscillating electric and magnetic fields that travel at the speed of light. Non-ionizing radiation includes the spectrum of ultraviolet (UV), visible light, infrared (IR), microwave (MW), radio frequency (RF), and extremely low frequency (ELF). Non-ionizing radiation is found in a wide range of occupational environments and can pose a significant health risk to potentially Exposed Employees if not controlled properly | Washington State L&I Cal/OSHA, and OSHA provide technical and regulatory information regarding the safety and health hazards associated with non-ionizing radiation. The International Commission on Non-Ionizing Radiation Protection (ICNIRP) is also a valuable resource for worker protection. |

| PPE | Personal protective equipment (commonly referred to as "PPE") is equipment worn to minimize exposure to various hazards. These hazards may result from contact with chemical, radiological, physical, electrical, mechanical, or other workplace hazards. | Washington State L&I, Cal/OSHA, and OSHA have PPE standards for various workplace applications. |

| Powered Industrial Trucks | There are many types of powered industrial trucks (PITs). Each type presents different hazards. For example, a sit-down truck is more likely than a motorized hand truck to be involved in a falling load accident because the truck can lift a load much higher than a hand truck can. Workplace type and conditions are also factors in hazards commonly associated with powered industrial trucks. | Washington State L&I, Cal/OSHA, and OSHA have set forth regulations on the safe use of PITs. |

| Spray Paint Operations | Spray operations can present both physical and health hazards to those involved. | The OSHA ventilation standard for general industry defines a "spray-finishing operation" as the "employment of methods wherein organic or inorganic materials are utilized in dispersed form for deposit on surfaces to be coated, treated, or cleaned." In addition, Washington State L&I has regulations on spray finishing operations and spray operations involving flammable and combustible materials. Cal/OSHA also has regulations that control hazardous dusts, fumes, mists, vapors, and gasses. |

| Tool & Equipment Safety | Power tools are widely used due to the ease of completing a task. While power tools and other tools make our jobs easier, hazards do exist from improper use (such as using proper guarding) or maintenance. | OSHA has standards for power tools. Washington State L&I regulates machine safety, portable power tools and the lock out/tag out (LOTO) process for controlling hazardous energies from these devices. Cal/OSHA has guidance for power tools and has general safety standards. |

| Welding and Soldering | Hot work is any work that involves burning, welding, using fire- or spark-producing tools, or that produces a source of ignition. OSHA considers hot work to include “welding or cutting operations, use of spark-producing power tools, and chipping operations.” Soldering is not considered hot work, but it does present hazards similar to those of other hot work activities (e.g., metal fumes and toxic materials). | Washington State L&I, Cal/OSHA, and OSHA provide regulations for hot work. Also, for soldering activities, both Washington State L&I, Cal/OSHA, and OSHA provide directives for the use and control of lead hazards, which are commonly associated with soldering.

|

General housekeeping is often overlooked but is very important in keeping Laboratory Employees and Maintenance Personnel safe.

4.1 Sweeping

Sweep all lab spaces after use or at the end of the day.

4.2 Cleaning Counters and Clutter

Keep countertops in all lab spaces and common areas clean and clutter-free when not in use.

Keep aisles free from materials and debris.

Place all tools, supplies, and other equipment in the proper storage location when not in use.

4.3 Lab Hygiene

The following are a few tips to maintain good lab hygiene:

Wipe down benchtop surfaces regularly to avoid contaminating the work or Employees’ clothing.

Replace bench liners when visibly contaminated.

Wash hands before donning and after removing gloves, and any time that hands may be contaminated.

Remove gloves before handling objects such as doorknobs, keyboards, telephones, and other objects that will be handled by co-workers without gloves to avoid contamination.

Wash hands before eating, drinking, smoking, or applying cosmetics.

Wear standard PPE (detailed below) when in the lab and remove any contaminated PPE before leaving the laboratory area.

Do not consume or store food and drink in areas used for laboratory operations.

Use designated clean areas for eating/drinking and food storage areas and observe good hygiene in these areas by not wearing gloves, using contaminated objects moved from other parts of the lab into these areas, and other non-hygienic practices.

Remove chemicals or other hazards from areas where maintenance personnel will need to work. Clean surfaces in those areas to limit exposure.

Dispose of broken glassware using broken glass disposal boxes.

Dispose of razor blades, needles, or other sharps in puncture-resistant hard-sided sharps disposal boxes. Use red sharps boxes ONLY to collect sharps that have been contaminated with blood or that pose a biological hazard. For all other sharps, use a collection container that is NOT red.

5.0 Battery Handling

Handle batteries properly to reduce the risk of battery incidents. Avoid the following conditions, which could cause a battery fire:

Over charging or discharging

Unbalanced cells

Excessive current discharge

Short circuits

Physical damage

Excessively hot storage

Poor electrical connections for multiple cells in one pack

Follow these best management practices for battery handling:

Purchase batteries from a reputable manufacturer or supplier. Cheap or counterfeit batteries may carry a higher likelihood of failing.

Take additional care with prototype batteries. Since they may not have passed the required safety testing, they present higher risk of failure.

Read all documentation supplied with the battery.

Avoid excessively hot and humid conditions, especially when batteries are fully charged.

Do not place batteries in direct sunlight, on hot surfaces, or in hot locations.

Never burn, overheat, disassemble, short-circuit, solder, puncture, crush, or otherwise mutilate battery packs or cells.

Do not put batteries in contact with conductive materials, water, seawater, strong oxidizers, and strong acids.

Inspect batteries for any signs of damage before use. Never use damaged or swollen batteries, and promptly dispose of them properly.

Comply with applicable electrical protection standards (e.g., terminal protection, shielding, PPE) to avoid exposure to electrical hazards. Lithium-ion batteries, assembled to offer higher voltages (more than 60 V), may present electrical shock and arc hazards.

Do not reverse the polarity of a battery.

Do not mix different types of batteries. Do not mix new and old batteries together (e.g., in a power pack).

Do not open the battery system or modules unless trained and permitted to do so.

Do not use the battery system without its protection circuits.

Immediately disconnect the batteries if, during operation or charging, they emit an unusual smell, radiate heat, change shape/geometry, or behave abnormally.

5.1 Battery Stress Dos and Don’ts

| Damage Type | DO follow these Safe Work Practices | DON’T do these activities without an SOP in place |

| Thermal Stress | Use welds to connect a battery to a terminal Discharge cells before heating | Soldering battery terminals Heating

|

| Mechanical Damage | Discharge cells before testing Use freezing method to remove adhered cells Use non-conductive, blunt tools for disassembly Consult ME’s to maintain battery clearances | Crushing, bending, puncturing Disassembling High pressure Removing cells fastened with pressure-sensitive adhesive (PSA) |

| Electrical Stress | Inspect batteries before use Ensure you know the polarity of the circuit and battery before energizing Ensure you know the capacity of the battery before charging | Using damaged batteries Reversing polarity of terminals Overcharging Over discharging Short-circuit Immersion in water |

5.2 Battery Storage

Follow these best management practices for battery storage:

Verify that there is a class ABC or CO2 fire extinguisher near the storage area.

Verify that there is a fire detector in the storage area.

Verify that there is a fire blanket in the storage area. Refer to the Fire Blanket section for more information.

See Fire Response section for more information. You can read more at Microsoft Fire Response.

Maintain a clean storage area. Keep it free from any materials that can catch fire such as wood tables, carpet, or gasoline containers. Store lithium-ion batteries on concrete, metal, ceramic, or any non-flammable material.

Do not store batteries in a refrigerator. Internal condensation may form when the battery is brought to room temperature, creating a dangerous situation.

Keep a dedicated area strictly for lithium-ion battery storage: a cool and dry place, away from heat sources.

Verify that batteries are not touching each other if stored in a metal cabinet such as a chemical storage cabinet.

Never leave batteries unsecured where someone else may cause damage.

Properly store loose Lithium polymer batteries and cells to prevent damage:

Avoid elevated temperatures and direct sunlight

Avoid contact with sharp objects or placing heavy objects on top of them

Don’t store them connected to a charger

Follow these best practices when storing lithium polymer batteries:

Individually wrapped for bulk storage and/or collection for recycling

Use bubble wrap, foam separators

Do not use foil, mylar, ESD bags

Use molded shipping trays from the manufacturer

5.3 Battery Removal

- Follow these practices for battery removal:

- Ensure that vent caps are functioning, if applicable. The battery (or compartment) cover(s) must be open to dissipate heat.

- Use mechanical lift systems for removal of heavy batteries.

- Prohibit smoking in the work area.

- Prevent open flames, sparks, or electric arcs in battery charging areas.

- Remove all metallic jewelry before recharging. Use non-conductive tools for removing batteries. Tools and other metallic objects must be kept away from the top of uncovered batteries.

- Where the eyes or body of any person may be exposed to injurious corrosive materials, provide an emergency eyewash station and shower within the work area for immediate emergency use.

5.4 Battery Disposal

Do not put batteries in the trash. There are two options for battery disposal and recycling.

For lithium polymer battery disposal – fill out a pickup request form. Someone will pick up your batteries, sort them, and properly dispose of them.

For other batteries – place these batteries in the battery recycling bin located in your building.

Don’t use the container to collect trash or chemical waste.

Place damaged, swollen, or leaking batteries in a sealed plastic bag individually before placing them in the battery bin.

For lithium-containing batteries, cover each battery’s terminals with electrical tape or place each in a re-sealable bag to prevent short-circuits with other batteries.

Do not use anti-static tape (e.g., ESD tape) to isolate terminals or ESD bags to collect batteries. These materials are electrically conductive.

For more information, refer to the Microsoft Battery Handling website. You can also refer to the Safety Data Sheet (SDS) for specific guidance on Ni-cad, lithium-ion, lead-acid, alkaline, and mixed battery disposal.

5.5 Battery Shipping

Lithium batteries are considered Hazardous Materials or Dangerous Goods by US Department of Transportation (DOT) and international transportation authorities.

There are special requirements for shipping lithium batteries and devices that contain them.

Shipments that include lithium batteries cannot be shipped through the US Post Office (USPS). Use a carrier that is certified to transport Hazardous Materials/Dangerous Goods.

Prototype batteries must pass safety tests before they are permitted in shipments.

Shipments of waste batteries are not allowed, except through a vendor approved by Microsoft OHS.

Before shipping batteries, consult one of the following resources:

Your team’s shipping subject matter expert

Mailing and Shipping: mailhelp@microsoft.com

Microsoft OHS: GlobalOHS@microsoft.com

6.0 Chemical Storage and Management

Refer to the Hazard Communication Plan, Chemical Hygiene Plan, and Hazardous Waste Management Plan for more information.

6.1 Introduction

Worker safety regulations require employers to inform Employees about hazards associated with hazardous chemicals present in the workplace. All laboratories must follow Microsoft’s Hazard Communication Program to address the chemicals present in the work area as well as Microsoft’s Chemical Hygiene Plan (CHP) requirements.

6.2 Chemical Hygiene Plan (CHP)

Laboratories must maintain a copy of the CHP: In addition:

Document safety procedures in the CHP.

Keep a copy of the CHP in the lab.

Verify that those working in the lab know to reference the CHP.

Be ready to present the CHP to regulators.

6.3 Hazard Communication

Chemical Hazard Communication regulations in the US align with the United Nation’s Globally Harmonized System of Classification and Labeling of Chemicals (GHS). GHS provides consistent and agreed upon criteria for the classification of chemical hazards. It standardizes hazard information on chemical labels, hazard pictograms, and SDS so that information communicated from the various manufactures to the end users is consistent.

Microsoft’s Hazard Communication Program applies to laboratories; industrial workplaces; manufacturing or commercial laboratories; and activities such as shops, custodial, craft centers, and other areas. The program requires Employees to:

Maintain a hazardous chemical inventory in Microsoft’s Chemical Inventory System.

Maintain and have access to SDSs (formerly called material safety data sheets).

Understand hazards associated with chemicals used in the lab through labeling and other warning methods.

Receive hazard communication safety training to minimize the risks associated with the hazardous chemicals used in the work area.

Develop, implement, and maintain a written Hazard Communications Program.

Participate in the Hazardous Waste Management Program.

Understand and follow the requirements of Microsoft’s Hazardous Waste Management Program. These policies cover procedures and timelines for chemical waste pickup.

Direct questions about chemical waste disposal to OHS at

Never dispose of chemicals, batteries, and electronic wastes in the trash or sanitary sewer without the previous written approval of OHS.

Avoid storing chemical wastes or batteries on the floor to reduce risk of spills. If storage on the floor is unavoidable, place the waste in secondary containment.

Hazard Awareness Training

Each Laboratory Worker must take a general laboratory safety course before beginning work in the lab and annually thereafter.

6.3.1 Laboratory-Specific Training

The Chemical Hygiene Officer or designated Lab personnel must conduct laboratory-specific hazard awareness training for each Laboratory Worker before that person begins working in the lab. This training will cover:

Laboratory-specific hazards

Standard Operating Procedures (SOPs)

Location of emergency response equipment

This Lab Safety Manual

6.3.2 Lab Safety Manager Training

The Lab Safety Managers from each lab must attend a one-time in-person training provided by OHS that includes:

Resources available to help the Lab Safety Manager develop lab-specific SOPs

Lab-specific training to present to Laboratory Workers

6.3.3 Required Chemical Hazard Information

6.3.3.1 Labels

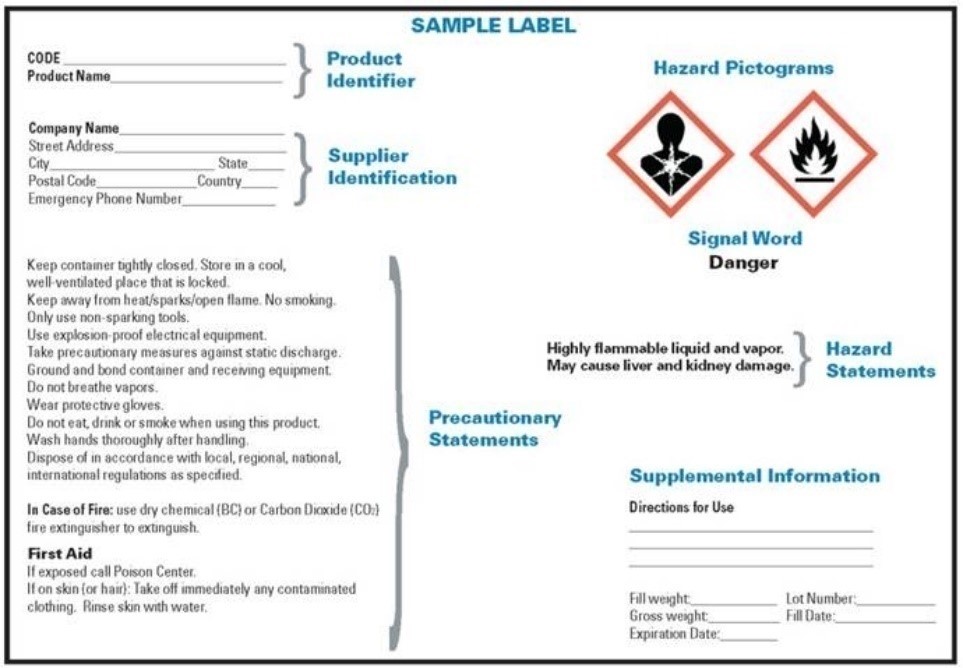

All containers of hazardous chemicals must be labeled. There are two types of containers: primary containers and secondary containers.

A primary container is the container that comes from the manufacturer. These containers must be labeled with the following information:

Product identifier

Signal word

Hazard statement(s)

Pictogram(s)

Precautionary statement(s)

Name, address, and telephone number of the chemical manufacturer, importer, or other responsible party

Secondary containers contain chemicals that have been transferred from the primary container. An example of a secondary container is a spray bottle or a small bottle of isopropyl alcohol used to hold enough of the chemical required for your work activity. Secondary containers must also be labeled with the chemical name, primary hazard, and owner (i.e., the person responsible for the container while working in the lab). This information may be written on the container.

6.3.3.2 Example Chemical Labels

Primary Container

Example Label

Secondary Container Example Label

6.3.3.3 Safety Data Sheets (SDSs)

A Safety Data Sheet (SDS) lists chemical hazards based on the OSHA Hazard Communication Standard. SDSs provide Laboratory Workers with information that will help them work with that substance in a safe manner. The SDS is used by emergency responders to help them treat patients who may have been exposed to the chemical. The SDS includes:

Ingredients

Physical and health hazards

Relevant exposure limits

Handling and storage recommendations

Physical and chemical properties

Reactivity

Toxicity

First aid

Fire-fighting and accidental release measures

Chemical manufacturers and importers are required to create an SDS for each hazardous chemical that they produce or import. These documents are available online for most major manufacturers; smaller manufacturers may distribute paper copies with the product.

Lab requirements for SDSs include:

Email a copy of any SDSs received to OHS for including in the online database.

Refer to the online SDS database, MSDSonline for access to Safety Data Sheets. You can access MSDSonline at https://aka.ms/msdsonline.

6.3.3.4 Signs and Posters

Verify that this information is posted outside of the lab. Customize the poster available in Appendix B: Lab Poster with:

Contact names and numbers for the laboratory

Emergency contacts numbers

After-hours contact information

The presence of hazardous activities in the laboratory

Laser hazards

Radioactive materials

Elevated noise levels

PPE requirements

Warning signage for specific hazards

Safety equipment in laboratories must also have appropriate signs including for fire extinguishers, emergency eyewash stations and showers, first aid kits, and spill kits. Other signage and documents that must be posted, as appropriate, inside the laboratory include:

Licenses/permits/certifications issued by regulatory agencies

SDSs available in MSDSonline

Emergency response posters

Warning signs on equipment (e.g., flammable materials, lasers, microwaves, high voltage, pinch/crush hazards)

Here are some quick tips to consider before using a chemical:

Read the label to understand potential hazards of a spill.

Develop a spill response procedure for the chemical and ensure that all who use that chemical understand how to respond to a release of the chemical.

Know how to use the spill kit.

Alert others in the lab of the danger.

In the event of a spill during use of the chemical:

Assess the severity of the emergency.

If unable to contain the spill or require assistance, contact 911 and Microsoft Global Security at 425.706.0000.

Follow instructions from the operator

For large releases, Microsoft Global Security may request emergency cleanup assistance from Clean Harbors.

Consider potential exposure through contact, inhalation, and the increased fire hazard associated with flammable materials.

Attempt to contain and/or clean up the release if all of the following are true:

Know the name of the chemical

Know the appropriate response procedures for the release of the chemical

Verify that you have the required response materials (sorbent, PPE, etc.)

Verify the response can be conducted safely (i.e., there are no other hazards or conditions in the area of the release that could harm you)

Individuals who cause the spill or were working with the spilled chemical are responsible for notifying the Lab Manager and Microsoft OHS as soon as the severity of the spill allows.

- Refer to the Incident Reporting and Investigation Plan for more information.

6.4 Chemical Hazard Controls

| Chemical hazards can be controlled in four ways: | |

| Elimination (including substitution) of Hazards | Remove the chemical hazard from the workplace or substitute the chemical with a less hazardous one. Look at the label and refer to the SDSs located on the online tool MSDSonline. |

| Engineering Controls | Engineering controls reduce or eliminate exposure to chemical or physical hazards through the use of equipment or devices. Engineering controls function with minimum user input and do not rely on skill or vigilance of individuals. |

| Administrative Controls | Alter the way the work is done, considering timing of work, policies and other rules, and work practices such as standards and operating procedures (including training, housekeeping, and equipment maintenance; PPE; and personal hygiene practices). |

| Personal Protective Equipment (PPE) | PPE refers to protective clothing, helmets, goggles, respiratory protection, or other garments or equipment designed to protect the wearer’s body from injury, infection, or chemical exposure. |

6.5 Work Practice Controls

| Prevent exposure by establishing rules for work practice and conduct. | |

| Housekeeping |

|

| Working Alone |

|

| Unattended Experiments/ Projects |

|

| Safe Use and Disposal of Sharps |

|

| Lab Equipment Safety |

|

| Chemical Handling |

|

| Food and Drink |

|

| Personal Hygiene |

|

| Minimizing Exposures for Maintenance Personnel |

|

6.6 Chemical Storage

Store chemicals in quantities that are as low as practical.

Make sure that all chemical containers are labeled according to requirements listed in the Hazard Communication section.

Store chemicals in compatible storage groups, and away from incompatibles – compatibility information should be included on the chemical’s SDS.

For additional guidance, check the list of Compatible Storage Groups in Prudent Practices in the Laboratory (National Research Council).

Store acids and bases separately.

Store flammables and oxidizers separately.

Store corrosives away from metal (unless the metal has a corrosion-proof coating). Do not store corrosives under the sink.

Store water reactives away from sinks and water-based solutions.

Use unbreakable secondary containers (e.g., a bin) for high-hazard materials.

Avoid storing chemical wastes or batteries on the floor to reduce risk of spills. If storage on the floor is unavoidable, place the waste in secondary containment.

Periodically examine stored chemical containers for container and label integrity. Replace faded or damaged labels. Contact Global OHS for instructions on how to dispose of leaking or damaged containers.

6.7 Chemical Transport

Take precautions to avoid dropping or spilling chemicals.

All hazardous materials deliveries must go through the Mailing and Shipping Department. These Employees are trained to handle and transport chemicals.

Need to figure out how to address cryogenic deliveries and bulk chemical deliveries (large containers)

Make sure that chemical containers are sealed during transport.

Carry breakable containers in specially designed bottle carriers or leak-resistant, unbreakable secondary containers.

Use a cart suitable for the load with high edges to contain leaks or spills. Verify that the cart can roll on uneven surfaces without tipping the chemical container or the cart.

Transport chemicals by traveling least-trafficked routes. When possible, use freight elevators.

Strap gas cylinders to a hand truck specifically designed for that purpose. Cylinder cover caps must be in place.

Contact OHS at GlobalOHS@microsoft.com before:

Relocating your lab chemicals to another space

Moving large amounts of chemicals or transporting chemicals via a public road

Shipping chemicals and hazardous materials

OHS will assist with safe packaging and compliance with federal, state, and local laws.

6.8 Chemical Disposal

Refer to Microsoft’s Hazardous Waste program for more information on chemical management and disposal, including chemical waste pickup.

ContactGlobal OHS with questions about chemical waste disposal.

Do not dispose of chemicals in the trash or down a sanitary sewer without the previous written approval of OHS.

Avoid storing chemical wastes on the floor to reduce risk of spills. If storage on the floor is unavoidable, place the waste bottle in secondary containment.

6.9 Spray Paint Operations

Paints, pigments, and thinners may contain flammable, volatile, and toxic solvents (e.g., alcohols, petroleum distillates, methyl ethyl ketone, formaldehyde, phenol, ammonia). Exposures can occur through inhalation and skin contact. Therefore, these products can cause respiratory irritation, sensitization, and allergic reactions.

Paint booths or spray booths are ventilated and fire protected, which helps capture and filter paint products. Along with ventilation, filters are used to capture paint and glaze contaminants and must be regularly replaced. Paint, dust, and pigment accumulation may prevent the hood from performing effectively. The user should be standing in line with the direction of airflow for the hood to work properly.

When conducting spray operations, the following actions must be implemented:

Prohibit open flames and ignition sources in paint storage areas.

Use premixed and/or water-based paints/inks rather than solvent-based, if possible.

Practice good hygiene; remove paint with baby oil, soap, and water.

Work in a well-ventilated area.

Operate mechanical ventilation during spraying operations and long enough thereafter to exhaust hazardous vapor concentrations.

Never spray solvent-based materials inside of the building except in designated spray booths.

Keep the spray booth clear of combustible materials.

Remove all ignition sources from the spray booth area.

Ensure that all spray gun equipment is grounded.

Wear protective clothing, gloves, safety goggles, and a face shield

Wear a respirator, as required by a risk assessment and authorization from OHS.

Keep all open flame or spark-producing equipment at least 20 feet away from a spraying area unless it is separated from the spraying area by a fire-retardant partition.

Do not locate hot surfaces in spraying areas.

Remove residue scrapings, debris, rags, and waste from the spraying area as they accumulate.

Remove discarded filters from the work area and dispose of them properly, as directed by OHS.

7.0 Electrical Safety and LOTO

Refer to the Electrical Safety Program and Lockout/Tagout (LOTO) Program for more information.

There are various methods of protecting people from the hazards caused by electricity, including insulation, guarding, grounding, and electrical protective devices. Laboratory Workers can significantly reduce electrical hazards by following some basic precautions:

Inspect wiring of equipment before each use. Do not use equipment with damaged or frayed electrical cords.

Use safe work practices every time when using electrical equipment.

Know the locations and how to operate shut-off switches. Use these devices to shut off equipment in the event of a fire or electrocution.

Limit the use of extension cords. Use these only temporarily. In all other cases, request installation of a new electrical outlet.

All electrical extension cords and multi-plug units must be connected directly to an electrical outlet (i.e., no daisy-chaining of power strips).

Place exposed electrical conductors (such as those sometimes used with anodizing equipment) behind shields.

Use equipment tested by a Nationally Recognized Testing Laboratory (NRTL) such as Underwriters Laboratory. OSHA has a list of current NRTLs.

If a piece of electrical equipment does not have the NRTL mark, do not use the equipment and contact OHS at Contact Global OHS with questions about chemical waste disposal. for solutions. Typically, test equipment from China will not have the mark. Additionally, equipment from the European Union will have the CE mark instead of the NRTL mark, so check with OHS before using it.

Minimize the potential for water or chemical spills on or near electrical equipment.

Ground fault interrupters (GFIs) are required for outlets located near a water source.

Never handle electrical equipment when hands, feet, or body are wet or perspiring or when standing on a wet floor.

Regard all floors as conductive and grounded unless covered with a well maintained, dry rubber matting of a type suitable for high voltage electrical work.

Use only one hand when working on a circuit or control device, when possible.

Avoid wearing rings, metallic watchbands, and other metallic objects while performing electrical work.

The following practices may reduce risk of injury or fire when working with electrical equipment:

Have a Written LOTO Program with a task specific LOTO description each time work is performed on equipment that requires LOTO.

Avoid contact with energized electrical circuits.

Use guarding around exposed circuits and sources of live electricity.

Disconnect the power source before servicing or repairing electrical equipment.

Make certain hands are dry and, when possible, wear non-conductive gloves and shoes with insulated soles when it is necessary to handle equipment that is plugged in.

If it is safe to do so, work with only one hand, keeping the other hand at your side or in a pocket, away from all conductive material. This precaution reduces the likelihood of accidents that result in current passing through the chest cavity.

Minimize the use of electrical equipment in cold rooms or other areas where condensation is likely. If equipment must be used in such areas, mount the equipment on a wall or vertical panel.

Shut off power at the main switch or circuit breaker and unplug the equipment if water or a chemical is spilled onto equipment.

Do not touch live electrical conductor(s), the equipment, cord, or person. Disconnect the power source from the circuit breaker or pull out the plug using a leather belt (or similar non-conductive tool).

Do not modify existing electrical services in a laboratory or building. This action must be completed or approved by either the Building Facility Manager or an Engineer from Microsoft’s Facilities Department. All modifications must meet both safety standards and Microsoft’s facilities engineering design requirements.

Investigate the cause of any tripped breaker before resetting it. You may only reset a breaker if you are certain it tripped due to an overload (and not an electrical fault).

Do not perform repairs on equipment that operates above 50V. Only properly trained Electricians may perform repairs of high voltage or high current equipment.

8.0 Lock Out/Tag Out Safety

The primary purpose of LOTO of a device or system is to prevent unintended releases of hazardous energy associated with servicing, maintenance, and other activities. Hazardous energy includes electrical, rotational, mechanical, radiation, chemical, hydraulic, or pneumatic energy sources. Where unexpected energization or startup of equipment or the release of stored energy could possibly result in injury, the equipment must be stopped, all potentially hazardous energy sources isolated, and equipment locked out and tagged out by each Worker before those Workers begin service, maintenance, and other activities.

Employees must be trained and qualified to install a LOTO lock and tag.

For more information please refer to the Microsoft Control of Hazardous Energy Program, and the OSHA LOTO Fact Sheet.

9.0 Emergencies and Incidents

Refer to the Emergency Action Plan (EAP), Evacuation Plan, Bloodborne Pathogens Plan, and Incident Reporting and Investigation Plan, for the specific location for more information.

In the event of an emergency, such as a fire or injury, follow these steps:

- Alert co-workers in the area.

- Assess the severity of the emergency.

- Call for help based on the severity of the incident. If unsure of severity, call 911.

- Evacuate the area and discourage people from re-entering before help arrives.

- Contact emergency response:

Call 911.

Microsoft Emergency Services 425.706.0000 On-site services can initiate a 911 response and provide guidance while Emergency Services are responding.

Do not attempt to move an unconscious person unless the nature of the emergency is certain.

9.1 General Fire Safety

Fires can be prevented by eliminating the source of ignition. When working with flammable materials, consider potential sources of ignition: open flames, sparks, and electrical sparks from motors.

9.2 Fire Response

9.2.1 Large Fires

If the fire is large, spreading, or out of control, activate the fire alarm to alert building occupants and do the following:

Shut down any equipment that may add fuel to the fire if possible.

Do not turn off any hoods in the immediate area, as they will tend to keep the area free from smoke and fumes.

Close the door upon exit to prevent the fire’s spread.

9.2.2 Small/Incipient Fires (no larger than a typical office trashcan)

Prompt action may prevent small fires from spreading out of control.

Alert others near the area and send someone for help.

Place an inverted glass or metal container (e.g., a beaker or a watch glass) over the fire to smother small fires in glassware.

If the fire is small and you have been authorized by OHS to use the fire extinguisher, you may attempt to put the fire out.

If the fire is too large to smother or extinguish with fire extinguisher, or if you haven’t been trained in the use of the fire extinguisher, evacuate the area.

Never attempt to fight a fire alone.

When fighting a fire, assume a position between the fire and the exit to ensure a means of escape.

If the fire can't be immediately controlled, call the fire department at 911. Activate the nearest alarm.

Try to contain the fire to the lab or room by closing fume hood sashes, windows, and the doors to the lab/room upon exit.

9.2.3 Fire Blankets and Portable Fire Extinguishers

If there is a fire, trained and authorized Employees can use a fire blanket or a fire extinguisher in response to the fire.

Store fire blankets in a centrally located area that is visible

Ensure portable fire extinguishers are present in their designated areas.

Maintain clear access to fire blankets and extinguishers at all times.

9.2.4 Burns & Burning Clothing

If clothing, skin, or hair catches fire:

Never run.

Stop, drop to the ground, and roll to smother the flames.

For others, help push them to the ground to prevent them from running and fanning the flames.

Use safety showers in the lab areas to put out a fire.

Send someone to call for help.

9.2.5 Metal Fires

Metal fires cannot be extinguished with regular extinguishers.

Use a Class D fire extinguisher or sand to smother the fire (CO2 and dry chemical extinguishers will intensify some types of metal fires).

Before starting work with metals such as sodium, potassium, magnesium, or powdered aluminum, verify that there is sand, or a Class D fire extinguisher located in the area.

9.3 Chemical Spill Response

Follow the Emergency Action Plan when responding to the chemical spill and refer to the Chemical Section of this document.

9.4 First Aid

First aid kits and Automated External Defibrillators (AEDs) are available in all Microsoft buildings. First Aid kits and AED’s are managed by

Laboratory Workers may request First Aid/CPR/AED training at the Living Well Health Center in B21 or RE&F

9.5 Eyewash Stations and Showers

Work areas must have an eye wash station when there is potential to splash corrosive or highly toxic chemicals into the eyes. A safety shower is required when there is a risk of contacting large parts of your body with corrosive or highly toxic chemicals. When present, these emergency washing facilities:

Must be located near the chemical work area (less than 10 sec travel time) with no doors or other barriers in the travel path between the washing station and the chemical work area

Must be inspected and serviced periodically

Must not be obstructed by stored items

Must conform to ANSI Z358.1

If chemicals or substances are spilled onto skin, eyes, or clothing take the following appropriate actions:

Promptly rinse eyes affected by a chemical spill. Continue rinsing for at least 15 minutes to prevent severe eye damage.

If another co-worker has a chemical splashed in their eye, assist them to the eyewash station and ensure that they rinse for at least15 minutes, even if it is uncomfortable.

Seek medical attention as soon as possible and bring the SDS of the chemical to the emergency room or physician’s office.

Notify the Lab Manager as soon as possible.

If a chemical affects the skin, immediately use the shower to rinse the exposed area of the body and continue rinsing for at least 15 minutes.

Remove all spill-contaminated clothing and rinse the exposed area for at least 15 minutes. Extra clothing should be available in the laboratory.

If the exposure is severe, call 911 for paramedics. Be sure to continue rinsing the exposed areas until directed to stop by the paramedics.

If the exposure is minor, rinse affected areas for at least of 15 minutes, seek medical attention, bringing the SDS.

9.6 Emergency Action Plans (EAPs) and Evacuation Plans

EAPs and Evaluation Plans are written to provide information to respond to emergencies. Laboratory workers should be familiar with the contents of these plans and participate in drills. EAPs can be found on .

9.7 Bloodborne Pathogens (BBP)

Employees must be trained and designated as responsible to render first aid. If you encounter blood or body fluids do not touch it and report it immediately. All first aid responders must use universal precautions when cleaning up blood or body fluids. All exposure incidents must be reported, investigated, and documented. See Microsoft Bloodborne Pathogen Plan for more information.

Following a report of an exposure incident, the exposed employee must be evaluated by a Licensed Healthcare Provider for a confidential medical evaluation and follow-up.

9.8 Incident Reporting

To foster a culture of health and safety at Microsoft, employees, interns, and external staff are required to report all work-related accidents, injuries, and illnesses via SafetyHub Report. Learn more on the Global OHS reporting page.

10.0 Ergonomics

This Lab Safety Manual only addresses ergonomic risks for laboratory environments, not offices. For more on office ergonomics (FTEs only), please refer to the Microsoft Ergonomics Program.

For more information on laboratory ergonomics, email the Microsoft Ergonomics Team at Global OHS

Ergonomics help us maximize productivity by reducing fatigue or discomfort caused by body position or repetitive movement. Ergonomic solutions aren’t just for your office. Laboratory workers may be exposed to ergonomic risks including overexertion, awkward postures/improper workstation setup, and repetitive motion. Specific risks for each category are listed below.

10.1 Overexertion

Wear comfortable shoes and consider using an anti-fatigue mat if the workstation requires standing.

Keep frequently used items within close reach. Most frequently used items should be at approximately a forearm’s reach away, with lesser-used items up to an arm’s reach away.

Keep shoulders, arms, and hands relaxed and elbows close to the sides while working.

Try to keep wrists neutral and aligned while working.

Use padding and/or tubing on equipment and work area edges to reduce pressure and force while working.

Use the lightest pressure possible to operate equipment (e.g., pipettes). Use electronic, automated, or light touch model equipment when possible.

Remember to take frequent rest breaks. Alternate grip on items like forceps.

Intensive tasks should be spread through the day or shared among Employees when possible.

Store heavy items on lower shelves.

10.2 Awkward Postures/Poor Workstation Setup

Use an adjustable chair or stool if seated at a bench top. Sit against the back of the chair. If feet come off the ground, lower the chair, adjust the foot ring, or get a footrest.

Adjust the position of the work, the work surface, or the chair or stool to enable working effectively while maintaining an upright, supported position.

Avoid hunching over work. For precision work, the work surface can be adjusted higher to provide support and reduce bending and hunching.

Regular light work generally places the work surface around elbow height or just below.

Heavy work places the work surface approximately 6 inches below elbow height.

If seated, ensure adequate room for legs.

If standing, use a foot rail to relieve pressure on the back.

Verify proper lighting for the task.

10.3 Repetitive Motion

Make sure all equipment is clean and in good working order to help minimize repetitive or forceful twisting, turning, and pinching. Equipment should be the right size for the hand.

Schedule work breaks when doing work with repetitive tasks.

11.0 Lasers

Refer to the Laser Safety Program for more information. This program provides controls and safety guidance for research and educational activities involving lasers.

Laser use can create intense concentrations of heat, ultraviolet, infrared, and reflected light radiation. Unprotected laser exposure may result in skin burns and eye injuries including retinal burns, cataracts, and permanent blindness. Always wear appropriate eye protection when working with lasers. The selection of laser protection, including skin protection, depends upon the lasers in use and the operating conditions.

11.1 Beam Hazards

Always protect the eyes from exposure to laser beams.

Choose laser goggles with wavelength-specific lenses and opaque non-lens components.

Never look directly into the laser beam. Eye exposure is most likely to occur during beam alignment.

11.2 Electrical Hazards

Lasers require electrical energy to operate and, as such, electrical hazards are present with lasers. Refer to the Electrical Safety and LOTO section of this document for safe work practices.

11.3 Other Hazards

Always consider other hazards such as compressed gases, explosion, fire, x-ray radiation, laser dyes and solvents, and mechanical hazards. In addition, laser-generated air contaminants are a concern, especially with Class 3B and 4 lasers. When these lasers are used, it is recommended to use local exhaust ventilation to capture and filter or exhaust outdoors the potential contaminants.

The American National Standards Institute (ANSI) has established a laser hazard classification system in publication ANSI Z136.1-2014, Safe Use of Lasers. Certified laser manufacturers are required to label their products as to the class type. The following table summarizes this laser classification scheme:

| Class | Laser and Laser System Classification |

| 1 |

|

| 1M |

|

| 2 |

|

| 2M |

|

| 3R and 3B (medium-powered) |

|

| 3R (previously called 3a) |

|

| 3B |

|

4 (high-powered)

|

|

Protective eyewear and visible warning lights near the entrance to laser areas (along with other controls) are required for Class 3 and 4 laser use where irradiation of the eye is possible. Such eyewear should be used only at the wavelength and energy/power for which it is intended. The Laser Safety Officer (LSO) will prescribe eye protection based on the risk assessment of the laser activities.

Contact LSO anytime for laser safety consultation or any of the following topics.

Safe alignment

Engineering controls

Laser safety eyewear

Specification

Purchase

Review Effectiveness

Near-miss review/lessons learned

General, non-beam safety reviews.

12.0 Powered Industrial Trucks (PITs)

Powered industrial trucks (PITs) include but are not limited to:

Forklifts

Motorized pallet jacks

Cargo haulers

PITs can expose Workers to hazards such as:

Being hit

Moving parts

Falls

Tip overs

Falling objects

Carbon monoxide from exhaust

Contact with corrosive battery acid (See battery section for details)

These hazards could lead to serious injuries that can result in hospitalization or death. Therefore, only trained, certified, and Authorized Employees can operate PITs. Each department is responsible for the proper maintenance of their PIT(s). Further information on proper operation/use of PITs is provided in the training for PIT Operators.

In order to operate a PIT you must first complete initial operator training for each type of PIT that will be operated. This will include hands-on training by a certified trainer. Refresher training is required at least every 3 years.

13.0 Personal Protective Equipment (PPE)

Refer to the Respiratory Protection Program and Hearing Conservation Program for more information. This program provides controls and safety guidance for research and educational activities involving lasers.

Refer to the Respiratory Protection Program and Hearing Conservation Program for more information. This program provides controls and safety guidance for research and educational activities involving lasers.

Refer to theRespiratory Protection Program and Hearing Conservation Program for more information. This program provides controls and safety guidance for Personal protective equipment, commonly referred to as "PPE," is equipment worn to minimize exposure to various hazards. PPE includes gloves, respiratory protection, eye protection, and protective clothing. The need for PPE depends on the type of operations and the nature and quantity of the materials in use. The use of PPE must be assessed on a case-by-case basis. Workers who rely on PPE must understand the functioning, proper use, and limitations of the PPE used.

13.1 Eye/Face Protection

13.1.1 Safety Glasses:

- Do not wear standard streetwear glasses.

Wear safety glasses whenever there is the possibility of objects striking the eye, such as particles, metal shards, or other debris.

Wear safety glasses with proper impact and shatter resistance marked "Z87" on the frame or lens.

Do not wear safety glasses when there is a possibility of significant chemical splash. Safety glasses do not offer adequate protection from significant chemical splashes. They do not seal to the face, which can result in gaps at the top, bottom, and sides, where chemicals may enter.

Wear chemical splash goggles when there is potential for splash from a hazardous material. Chemical splash goggles should have indirect ventilation so hazardous substances cannot enter the eye area. Some are made to be worn over prescription glasses.

Wear face shields when working with large volumes of hazardous materials.

Wear face shields when working with corrosives and there is not an emergency eye wash station located within a 10-second walking distance.

OHSA regulations require that Employees who wear prescription lenses while engaged in operations that involve eye hazards shall wear eye protection that incorporates the prescription in its design, or must wear eye protection that can be worn over the prescription lenses (goggles, face shields, etc.) without disturbing the proper position of the prescription lenses or protective lenses. Any prescription eyewear purchase must comply with ANSI Z87.1-1989. Contact lenses by themselves are not considered as protective eyewear. The need for protective eyewear will be described in the risk assessment for the work activity. Employees interested in obtaining prescription safety glasses should contact their supervisor or Lab Manager.

13.2 Protective Clothing

Wear lab coats when there is a possibility of minor chemical splashes and solids contamination chemical contamination.

Wear protective clothing that resists physical and chemical hazards worn over street clothes when there is a possibility of major chemical splashes, and solids or chemical contamination.

Wear plastic or rubber aprons for protection from corrosive or irritating liquids.

Do not wear loose clothing (such as overlarge lab coats or ties), clothing that exposes the skin (such as shorts), torn clothing, or unrestrained hair, as these may pose a hazard in the laboratory.

13.3 Footwear

Wear closed-toed sturdy shoes in buildings where chemicals are stored or used and mechanical work is conducted. Perforated shoes, sandals, or cloth sneakers should not be worn in laboratories or where mechanical work is conducted. Such shoes offer no barrier between the Laboratory Worker and chemicals, broken glass, heavy objects, and other hazards.

Wear chemical-resistant overshoes or boots to avoid possible exposure to corrosive chemicals or large quantities of solvents or water that might penetrate normal footwear (e.g., during spill cleanup). Leather shoes tend to absorb chemicals and may have to be discarded if contaminated with a hazardous material.

Wear safety-toed shoes when there is a risk of heavy objects falling or rolling onto the feet, which is generally not required in most laboratories.

13.4 Gloves

Wear protective gloves when handling:

Hazardous materials

Chemicals of unknown toxicity

Corrosive materials

Rough or sharp-edged objects

Very hot or very cold materials

When handling chemicals in a laboratory, disposable latex, vinyl, or nitrile examination gloves are usually appropriate for most circumstances and offer protection from incidental splashes or contact.

When working with chemicals with high acute toxicity, working with corrosives in high concentrations, handling chemicals for extended periods of time, or immersing all or part of a hand into a chemical, the appropriate glove material should be selected based on chemical compatibility.

The following table includes major glove types and their general uses.

| Glove Material | General Uses |

| Butyl | Offers the highest resistance to permeation by most gases and water vapor. Especially suitable for use with esters and ketones. |

| Neoprene | Provides moderate abrasion resistance but good tensile strength and heat resistance. Compatible with many acids, caustics, and oils. |

| Nitrile | Excellent general duty glove. Provides protection from a wide variety of solvents, oils, petroleum products, and some corrosives. Offers excellent resistance to cuts, snags, punctures, and abrasions. |

| PVC | Provides excellent abrasion resistance and protection from most fats, acids, and petroleum hydrocarbons. |

| PVA | Highly impermeable to gases. Provides excellent protection from aromatic and chlorinated solvents. Cannot be used in water or water-based solutions. |

| Viton | Provides exceptional resistance to chlorinated and aromatic solvents. Provides good resistance to cuts and abrasions. |

| Silver Shield | Resists a wide variety of toxic and hazardous chemicals. Provides the highest level of overall chemical resistance. |

| Natural rubber | Provides flexibility and resistance to a wide variety of acids, caustics, salts, detergents, and alcohols. |

Most glove manufacturers have chemical compatibility charts available for their gloves. Also, the AnsellPro Glove Selection Guide is a good source for more detailed information.

13.5 Welding and Cutting PPE

PPE is also important for welding and cutting operations. For welding operations, wear:

Eye protection

Face protection

Hand/arm protection

Head and body protection

Such welding, cutting, brazing, grinding, or other spark-producing operations PPE may include:

Leather gloves

Leather apron

Gauntlets

Safety glasses with side shields

Welders helmet or welder’s goggles

The intense light associated with welding operations can cause serious and sometimes permanent eye damage if operators do not wear proper eye protection. The intensity of light or radiant energy produced by welding, cutting, or brazing operations varies depending on the type of task that produces the light, the electrode size, and the arc current. The following table shows the minimum protective eyewear for a variety of welding, cutting, and brazing operations for some hot work activities:

| Shade Number | Welding/Cutting Operations |

| 10 | Shielded metal-arc welding (SMA) 1/16-, 3/32-, 1/8-, 5/32-inch diameter electrodes |

| 12 | SMA 3/16-, 7/32-, 1/4- inch diameter electrodes |

| 14 | SMA 5/16-, 3/8-inch diameter electrodes |

| 11 | Gas-shielded arc welding (nonferrous) 1/16-, 3/32-, 1/8-, 5/32- inch diameter electrodes |

| 12 | Gas-shielded arc welding (ferrous) 1/16-, 3/32-, 1/8-, 5/32-inch diameter electrodes |

| 14 | Carbon-arc welding |

| 3 or 4 | Torch brazing |

| 3 or 4 | Light cutting, up to 1 inch |

| 4 or 5 | Medium cutting, 1 to 6 inches |

13.6 Soldering PPE

For soldering operations, the following PPE must be worn:

Long sleeve shirts and pants made of natural fibers (cotton) to prevent burns from splashes of hot solder

Closed‐toe shoes

Safety glasses, goggles, or face shields when soldering and clipping wires

13.7 Respiratory Protection

A respirator may only be used when engineering controls, such as general ventilation or a fume hood, are not feasible or do not reduce the exposure of a chemical to acceptable levels. Because the use of a respirator is regulated by the OSHA Respiratory Protection Standard, respirator use at Microsoft is subject to prior review and authorization by OHS.

Any Worker who believes that respiratory protection is needed must:

Notify OHS for evaluation of the hazard and enrollment in the Respiratory Protection Program.

Select a proper respirator with the help of OHS.

Go through the medical evaluation and fit testing processes.

Attend Employee training

13.8 Hearing Protection

Most laboratory equipment and operations do not produce noise levels that require the use of hearing protection, although there are several areas where noise levels are elevated. Microsoft has an established Hearing Conservation Program in place for individuals exposed to noise levels equal to or exceeding the OSHA action level of 85 decibels (dBA) averaged over 8 hours, per the OSHA Occupational Noise Standard. This program includes workplace monitoring, personal exposure monitoring, annual audiometric testing, use of hearing protection, and annual training.

Laboratory Workers who would like to use hearing protection for noise levels below the action level may do so without enrollment in the Hearing Conservation Program.

14.0 Radiation Safety

Refer to the Non-Ionizing Radiation Safety Program and local plan for more information, which includes the level of PPE required for working with radiation. Also refer to the Ionizing Radiation Safety Program for more details. radiation. Also refer to the Ionizing Radiation Safety Program for more details.

14.1 Ionizing Radiation

Ionizing radiation emits charged particles produced when electrons are removed from atoms. Ionizing radiation includes x-rays and gamma rays. This type of radiation can change cells in the body by breaking the chemical bonds holding molecules together, including DNA molecules. Ionizing radiation safety begins with Lab Managers providing lab-specific training to their personnel regarding occupational risks associated with their specific radionuclides, radiation-generating machines, and procedures.

Washington State L&I and OSHA regulations require that Employees who work with ionizing radiation and radioactive material(s) be adequately trained to allow them to conduct their work safely. This training must include:

Information on the potential hazards associated with the use of radioactive material and how these hazards can be minimized

Emergency procedures

Procedures for the procurement, use, and disposal of radioactive material

Ionizing radiation controls primarily rely on engineering and administrative controls. These controls include, but are not limited to:

Shielding - Minimize exposure by placing absorbing shield between Worker and source.

Distance - Maximize distance to source to maximize attenuation in air.

Timing - Minimize time of exposure to minimize total dose. Rotate Employees to restrict individual dose.

Training – Prepare Employees to handle ionizing radiation safely.

Documenting - Conduct surveys such as using personal dosimeters or direct reading instruments.

Employees are required to comply with the appropriate regulations, complete contamination surveys, verify all personnel participate in the dosimetry program, and, if applicable, inform women about the Declared Pregnant Worker Program.

OHS provides the following support when working with radioactive materials and radiation-generating machines:

Evaluate the safety of the various activities and facilities.

Monitor radiation exposures and assess environmental and personnel doses.

Respond to radiological emergencies and radioactive spills.

Recommend monitoring equipment appropriate to the source of radiation.

Apply for regulatory licenses and registrations.

Provide safety training on exposure and contamination control, risk assessment, and instrumentation usage.

14.2 Non-Ionizing Radiation (Non-Lasers)

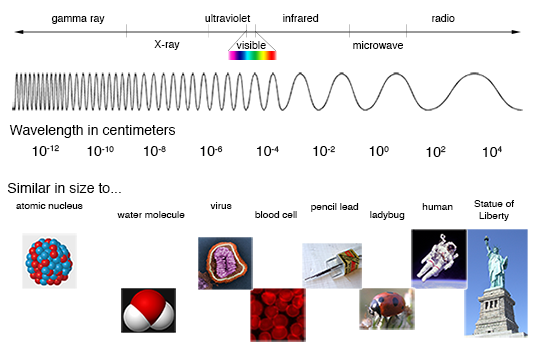

Non-ionizing radiation (NIR) refers to electromagnetic radiation with insufficient energy to release a bound electron from an atom. NIR includes the following categories of radiation:

Ultraviolet (UV)

Visible light

Infrared

Radio frequency

Microwave

Magnetic fields

Similar to ionizing radiation, the controls for NIR include, but are not limited to:

Shielding, distance, timing

Training

Conducting surveys

Like ionizing radiation, such as x-rays and gamma rays, NIR is a part of the electromagnetic (EM) spectrum and is emitted as waves through a vacuum or a different medium. Nevertheless, NIR differs from ionizing radiation because it consists of lower energies and, therefore, has different biological effects.

The OHS Department provides safety information and monitors exposures to operators with NIR equipment to reduce risk of injury and prevent overexposure.

14.3 Electromagnetic Spectrum

15.0 Tools & Equipment

Power tools and hand tools can allow for efficient work if used properly.

For machine tools, machine equipment, and power tools:

Routinely inspect for damage.

Verify that the controls function as designed.

Verify that all guarding and shields are securely installed and adjustable.

Clean, lubricate, maintain, and adjust machine equipment and machine tools to help prevent performance and safety problems.

When servicing equipment:

Only allow Qualified Individuals or Qualified Vendors to service equipment.

Verify that all electrical, hydraulic, compressed air, and stored-energy sources are secured before servicing. Refer to Electrical Safety and LOTO for more information.

15.1 Power Tools

Power tools must be fitted with guards and safety switches; they are very hazardous when used improperly. The types of power tools are determined by their power source: electric, pneumatic, liquid fuel, hydraulic, and powder-actuated. To prevent hazards associated with the use of power tools:

Never carry a tool by the cord or hose.

Never pull by the cord or the hose to disconnect it from the receptacle.

Never use a power tool when the ground prong has been removed or the insulation on the cord is frayed/missing or damaged in any way.

Keep cords and hoses away from heat, oil, and sharp edges.

Disconnect tools when not using them; before servicing and cleaning them; and when changing accessories such as blades, bits, and other components.

Keep all people not involved with the work at a safe distance from the work area.

Secure the work piece with clamps or a vise, freeing both hands to operate the tool.

Avoid accidental starting. Do not hold fingers on the switch button while carrying a plugged-in tool.

Maintain tools with care; keep them sharp and clean for best performance.

Follow instructions in the user’s manual for lubricating and changing accessories.

Be sure to keep good footing and maintain good balance when operating power tools.

Wear proper apparel for the task. Remove loose clothing, ties, or jewelry that may be caught in moving parts.

Remove all damaged portable electric tools from use and tag them: “Do Not Use.”

15.2 Hand Tools

Follow these requirements for using hand tools:

Know how to properly use hand tools by taking the proper training.

Damaged tools:

Do not use damaged tools.

Report damaged tools to the Lab Safety Manager.

Remove damaged hand tools from service and tag them “Do Not Use.”

Saw blades, knives, or other sharp tools:

Direct the tools away from aisle areas and away from other Laboratory Workers nearby.

Keep knives and scissors sharp. Dull tools can cause more hazards than sharp ones. Dull tools require more force than sharp ones—with more force exerted, you will have less precise control over the tool. Additionally, a dull tool is less precise than a sharp one and cuts may become unpredictable and unsafe.

Remove cracked saw blades from service.

Do not use wrenches when jaws are sprung to the point that slippage occurs.

Do not use damaged impact tools. These tools, such as wedges and chisels, should not have of mushroomed heads.

Do not use tools with wooden handles that are splintered or damaged.

Iron or steel hand tools:

Be aware that these tools may produce sparks that can ignite flammable materials.

Use spark-resistant tools made of non-ferrous materials when working in a fire hazard (e.g., in the presence of flammable gases, highly volatile liquids, and other explosive substances).

Wear appropriate PPE, such as safety goggles and gloves, to protect against hazards.

Keep workplace floors as clean and dry as possible to prevent accidental slips with or around dangerous hand tools.

The Lab Safety Manager must verify that machine-tool and machine-equipment guarding is adequate. Guarding may be achieved by one or more methods, such as use of isolation, barriers, shields, engineered devices (e.g. light curtains), or distance.

Do not remove factory-installed guards unless they are designed to be removed for a particular operation, and equivalent means of protection are used (e.g., when table saw guards are removed for fence cuts use push sticks or push blocks).

Verify guarding on all reasonably accessible points of operation, pinch and nip points, rotating parts, and flying chip or spark hazards that may expose an Employee to injury. Guarding prevents inadvertent contact with these hazards.

16.0 Welding and Soldering

16.1 Welding

Some Microsoft teams have a need to conduct welding, cutting, or open flame operations (referred to as “hot work”). Potential health, safety, and property hazards can result from the fumes, gases, sparks, hot metal, and radiant energy produced during hot work. Hot work equipment, which may produce high voltages or use compressed gases, also requires special awareness and training on the part of the Worker to be used safely. Furthermore, it is also important to ensure that persons near the welding operations are prohibited from entering areas where welding is occurring. Please reference the specific work plan for the type of welding/cutting operation for more details.

Areas where hot work is conducted should be properly designated and prepared. Combustible and flammable materials within the work area should be protected against fire hazards, and the operation should not pose a hazard to others in nearby areas. To help achieve this, the following controls should be used:

Only allow Authorized Employees and properly trained individuals to perform hot work operations.

Each hot work activity must have a written procedure that describes the work and safety controls in place.

Complete hot work permits before each hot work activity. See appendices for the Hot Work Permit.

Wear proper PPE for all welding and cutting operations. Please refer to the PPE section for details.

Use adequate ventilation when performing hot work indoors (i.e., a local exhaust hood).

Always consider other hazards such as compressed gases.

Move combustible materials at least 35 feet from the work site. If this is not possible, protect combustible materials with metal guards or by flameproof curtains or covers (other than ordinary tarpaulins).

Cover floor and wall openings within 35 feet of the work site to prevent hot sparks from entering walls or falling beneath floors or to a lower level.

Use fire-resistant curtains and/or tinted shields to prevent fire, Employee burns, and ultraviolet light exposure.

16.2 Soldering General Safety

Soldering operations are another important task conducted at Microsoft. Potential health, safety, and property hazards can result from soldering include fumes from the solder and flux materials, burns from hot metal, fires, and electrical issues with the soldering iron The following safety items cover soldering work:

Soldering work stations must have the following elements:

Local exhaust ventilation

Automatic shut-off

Free of combustible items in the immediate work area

Free of food, drinks, cosmetics, etc. to avoid ingesting metal contamination

Do not conduct soldering activities at desks or other office areas.

Never touch the element or tip of the soldering iron. It is very hot (about 400 °C) and will burn.

Hold wires to be heated with tweezers, pliers, or clamps to avoid receiving burns from heated objects.

Keep the cleaning sponge wet during use.

Conduct soldering on a stable, level surface and return the soldering iron to its stand when not in use. Never place the iron down on the workbench.

Turn the unit off or unplug the iron when not in use. Soldering stations that feature an automatic shutoff not only extend the life of tip, iron, and station, but provide an additional measure of fire safety.

Follow manufacturer’s instructions and read and understand the SDSs for all materials before beginning work.

Conduct work in a well-ventilated area or use the local exhaust filters provided at each soldering station.

Avoid breathing fumes/smoke by keeping head to the side of, not above, the work. The addition of a small fan that blows from behind the Worker across the work area can help move fumes away from the breathing zone.

Use lead-free or low-lead solder whenever possible.

Conduct work on a non-combustible work surface.

Remove combustible items from the work area.

Wear non-flammable or 100% cotton clothing that covers the arms and legs to help prevent burns.

Be sure the iron is secure in its stand so it cannot inadvertently dislodge onto the work surface.

Keep cleaning solvents in dispensing bottles to reduce inhalation hazards.

Always wash hands with soap and water after soldering.

Avoid ingestion of lead surface contamination by keeping soldering areas clean and properly managing lead soldering waste (see waste section below).